Introduction: Industrial Heating is Evolving—Fast

In the world of manufacturing, energy efficiency and precision are no longer optional—they’re essential. As we step into 2025, the future of industrial heating is being redefined by technological innovation, environmental regulations, and the global push toward sustainability.

From automotive to aerospace, food processing to pharmaceuticals, every sector relying on thermal processes is under pressure to optimize heat usage, cut emissions, and reduce operational costs. And this transformation is being driven by the evolution of industrial heating technologies.

This article explores the top industrial heating trends of 2025, helping engineers, manufacturers, and energy managers prepare for what’s next—and why partnering with experts like Encon Thermal Engineers is critical in staying ahead.

⚙️ 1. Electrification of Heat: Moving Away from Fossil Fuels

One of the biggest industrial heating trends in 2025 is the shift from fossil-fuel-based systems to electric heating solutions. As governments tighten carbon emission norms and introduce clean energy incentives, industries are looking for ways to decarbonize heat generation.

Why This Matters:

- Electric heating systems can achieve precise temperature control

- They are easier to automate and integrate with Industry 4.0 systems

- When paired with renewable energy sources, they offer zero-emission heating

Electric infrared heaters, induction heating, and resistance-based systems are gaining traction across metal, plastic, glass, and food industries—setting the stage for a greener future.

🌿 2. Energy Recovery Systems: Turning Waste into Savings

The future of industrial heating is also about maximizing what you already have. In 2025, energy recovery systems are becoming standard in thermal processes. These systems capture waste heat from exhaust gases or flue streams and reuse it to preheat combustion air, process fluids, or other stages in production.

Key Benefits:

- Reduces overall energy consumption

- Lowers fuel costs and environmental footprint

- Improves system efficiency by up to 20–30% in many cases

At Encon Thermal Engineers, we specialize in designing customized heat recovery solutions, including recuperators, economizers, and waste heat recovery boilers tailored for diverse industries.

🧠 3. Smart Heating Systems and IoT Integration

The future of industrial heating is also about maximizing what you already have. In 2025, energy recovery systems are becoming standard in thermal processes. These systems capture waste heat from exhaust gases or flue streams and reuse it to preheat combustion air, process fluids, or other stages in production.

What Smart Heating Looks Like:

- Real-time monitoring of temperature, pressure, and energy flow

- Predictive maintenance using data analytics

- Automated system adjustments to reduce overheating or downtime

These smart heating systems help plants optimize performance, reduce unplanned maintenance, and improve energy usage—leading to higher ROI over time.

🔁 4. Modular & Scalable Heating Designs

Flexibility is the name of the game in 2025. With product lines changing frequently and production volumes varying, companies now prefer modular heating solutions that can scale up or down easily.

Modular Industrial Heating Offers:

- Faster installation and commissioning

- Easy expansion or reconfiguration

- Reduced footprint, ideal for compact plant layouts

Encon’s modular heating solutions are already being used in food processing, ceramics, and chemical industries, helping clients adapt quickly to market demand without heavy reinvestments.

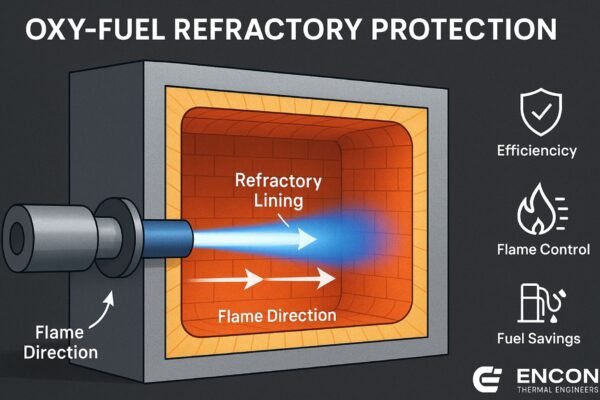

♻️ 5. Focus on Low-NOx and Cleaner Combustion

Environmental responsibility isn’t just good PR—it’s a regulatory requirement. With new standards being enforced globally, low-NOx burners and clean combustion systems are in high demand.

Future-ready burners will offer:

- Significantly reduced nitrogen oxide (NOx) emissions

- Better fuel-air mixing for cleaner combustion

- Compatibility with biofuels and hydrogen blends

Encon’s modular heating solutions are already being used in food processing, ceramics, and chemical industries, helping clients adapt quickly to market demand without heavy reinvestments.

⚡ 6. Alternative Fuels and Hybrid Heating

The future of industrial heating is not just about electrification—it’s about diversification. In 2025, we’re seeing an uptick in the use of alternative fuels like biogas, syngas, and even green hydrogen, especially in countries leading the renewable energy charge.

Some industries are also adopting hybrid heating models, where systems can switch between electric and gas modes based on availability, cost, or grid load.

At Encon, our R&D team is already working on next-gen hybrid industrial heating technologies that balance sustainability with performance.

🔍 7. Process Optimization Through Thermal Simulation

Before installing or upgrading a heating system, forward-thinking companies are now turning to thermal modeling and simulation. These digital tools help visualize heat flow, identify bottlenecks, and predict the impact of design changes without physical prototyping.

Benefits of Simulation:

- Lower design risk

- Reduced trial-and-error costs

- Improved throughput and uniformity

Combined with Encon’s engineering expertise, thermal simulation ensures every heating system is optimized before it hits the production floor.

🌐 8. Global Supply Chain Resilience and Localization

COVID-19 and geopolitical instability taught us that supply chain flexibility is essential. In 2025, industries are rethinking their vendor and component sourcing strategies. There is a clear move toward local manufacturing, regional partnerships, and long-term vendor reliability.

Encon Thermal Engineers continues to invest in in-house manufacturing, quality control, and faster deployment—ensuring that clients receive dependable service, even during global disruptions.

Conclusion: The Future of Industrial Heating Starts Now

The future of industrial heating is driven by sustainability, intelligence, and innovation. Whether it’s electric systems, energy recovery, smart automation, or clean fuels—2025 marks a turning point in how industries generate and use heat.

Manufacturers who adapt quickly will enjoy:

- Lower energy bills

- Better product quality

- Stronger compliance

- A competitive edge in the global market

At Encon Thermal Engineers, we’re not just watching the trends—we’re building them. With over three decades of experience and a deep commitment to engineering excellence, we help our clients implement future-ready industrial heating solutions that are efficient, scalable, and sustainable.

📞 Stay Ahead with Encon

Whether you’re upgrading an existing furnace, planning a new plant, or exploring energy recovery systems—Encon Thermal Engineers is your trusted partner in navigating the industrial heating trends of 2025 and beyond.

🌐 Website: [https://encon.co.in/]

📧 Email: sales@encon.co.in

📞 Contact: +91-9650900279

🔥 Future-ready heating starts with future-ready thinking. Connect with Encon today.