Introduction: Energy Efficiency – The Industrial Imperative

In today’s competitive manufacturing environment, energy efficiency is no longer a choice—it’s a necessity. Rising fuel prices, stricter environmental norms, and the global push toward sustainability have compelled factories to rethink how they consume energy.

But for many industrial units, especially in developing markets, implementing large-scale energy-saving projects can seem risky or financially out of reach.

Enter the ESCO model for factories—a smart, performance-based partnership that delivers both savings and sustainability without upfront investment.

In this blog, we’ll break down what the ESCO model is, explore how ESCO improves factory efficiency, and show why more and more manufacturers are turning to this model to stay profitable and planet-friendly.

What is the ESCO Model?

ESCO stands for Energy Service Company. Under this model, an ESCO like Encon Thermal Engineers partners with a factory to implement energy-saving solutions. Instead of paying for equipment or upgrades upfront, the client pays from the cost savings generated by those improvements.

It’s a performance-based contract—if savings aren’t achieved, the ESCO doesn’t get paid.

How the ESCO Model Works for Factories

Here’s a simplified flow of how the ESCO model for factories works:

- Energy Audit: The ESCO conducts a detailed energy audit of the plant to identify inefficiencies and opportunities for savings.

- Project Design: Custom solutions are proposed, ranging from waste heat recovery to burner upgrades and process automation.

- Implementation: The ESCO installs, commissions, and manages the project with minimal disruption to operations.

- Performance Monitoring: Savings are tracked and verified over time.

- Payment from Savings: The factory shares a portion of the cost savings with the ESCO over an agreed period.

At the end of the contract, the client owns the system entirely, continuing to benefit from savings for years to come.

How ESCO Improves Factory Efficiency

The ESCO model brings in more than just capital—it brings technical expertise, accountability, and performance-based execution.

Let’s break down how ESCO improves factory efficiency in real terms:

- Targeted Upgrades Based on Data: Unlike generic equipment upgrades, ESCOs work on data-driven insights from energy audits. This ensures that every rupee invested goes into systems that deliver maximum savings per unit of energy.

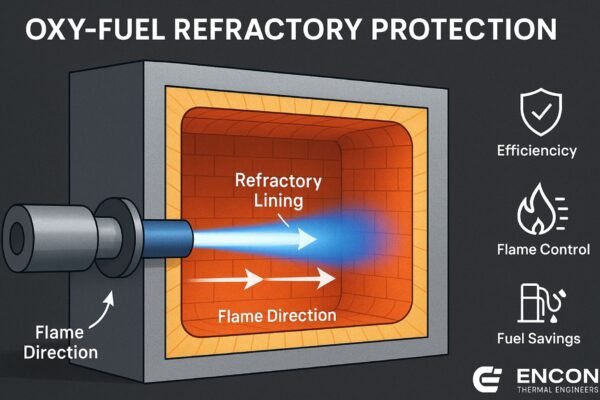

- State-of-the-Art Technology: Whether it’s high-efficiency burners, heat recovery units, or intelligent controls, ESCOs bring in best-in-class industrial technologies that factories may not access otherwise.

- End-to-End Project Execution: ESCOs handle everything—from design and procurement to installation and monitoring—eliminating operational burdens on the factory team.

- Continuous Monitoring & Optimization: Ongoing performance tracking ensures that systems run at optimal levels, with real-time insights and periodic fine-tuning for continued savings.

By combining expertise with execution, ESCOs become long-term efficiency partners for factories aiming to compete globally.

Reducing Energy Costs in Factories—Without Upfront Capital

Many manufacturers know they’re losing money on inefficient systems, but budget constraints hold them back.

The ESCO model solves this by eliminating upfront capital investment. Since the ESCO recovers its cost from the client’s energy savings, there’s no need for loans, CAPEX, or delays.

Clients start saving from day one, with many projects delivering ROI in 1–3 years, followed by a decade or more of sustained benefits.

With Encon Thermal Engineers, projects are structured transparently, with clear savings projections, timelines, and post-project support.

Case Snapshot: Heat Recovery in a Textile Plant

Challenge: A textile manufacturing unit in Gujarat was losing significant heat through exhaust gases. They wanted to reduce their fuel costs but had limited capital to invest.

Encon’s ESCO Solution:

- Conducted a thermal audit

- Designed and installed a waste heat recovery unit

- Recovered heat was reused for boiler feedwater preheating

Results:

- Fuel savings of 18% annually

- Zero upfront investment from the client

- Payback achieved in 24 months through shared savings

- CO₂ emissions reduced by 210 tons/year

This is just one example of how ESCO improves factory efficiency while aligning economic and environmental goals.

Environmental Compliance Made Easy

Sustainability is no longer just a buzzword—factories must now meet global standards like ISO 50001, BEE ratings, and state-specific pollution norms.

ESCOs help manufacturers reduce emissions, improve energy performance metrics, and generate the documentation needed for regulatory or CSR reporting.

Through Encon’s ESCO model, clients don’t just save money—they future-proof their operations for compliance and reputation.

Conclusion: Partnering for a Smarter, Greener Future

As industries face rising energy prices and growing environmental responsibilities, the ESCO model for factories offers a win-win framework that delivers real, measurable results.

From reducing energy costs in factories to deploying cutting-edge industrial heating and recovery systems, ESCOs like Encon Thermal Engineers are making efficiency easy, affordable, and impactful.

Ready to Boost Your Factory’s Efficiency?

Whether you’re planning a retrofit or want to identify savings in your current setup, Encon’s ESCO team can help you unlock energy and cost efficiencies, without upfront risk.

📧 Email: sales@encon.co.in

🌐 Website: [https://encon.co.in/]

📞 Call Us: +91-9650900279

📍 Encon Thermal Engineers – India’s Trusted Partner in Industrial Energy Solutions