Introduction

The global energy landscape is undergoing a major transformation. With rising climate concerns and international pressure to reduce greenhouse gas emissions, industries are seeking cleaner and more sustainable fuels. Among the front-runners of this energy transition are hydrogen and natural gas.

While natural gas has long been the cleaner alternative to coal and oil, the focus is now shifting toward hydrogen fuel in industrial heating. But how do these two compare? What are the trade-offs, and what’s the future of industrial combustion?

This blog delves deep into the debate of Hydrogen Combustion vs. Natural Gas, helping you understand the key differences, benefits, challenges, and what it means for the future of industrial heating.

Understanding the Basics

What is Natural Gas Combustion?

Natural gas is primarily composed of methane (CH₄). It has been widely used in industrial furnaces, boilers, and kilns due to its relative cleanliness compared to coal or oil.

Natural gas combustion emits carbon dioxide (CO₂) and nitrogen oxides (NOx), both of which contribute to climate change and air pollution. However, it is still considered a transitional fuel due to its widespread availability and lower emissions than other fossil fuels.

What is Hydrogen Combustion?

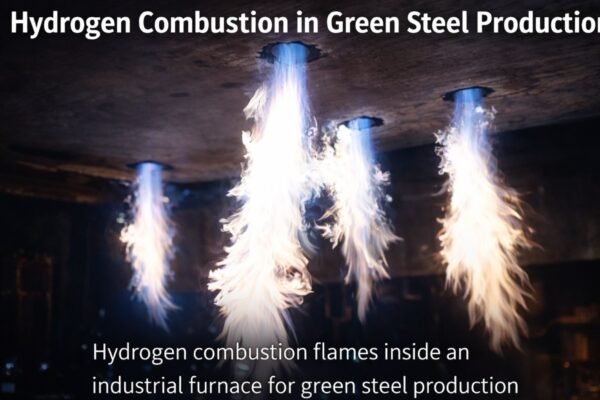

Hydrogen is the most abundant element in the universe. When burned, it produces only water vapor (H₂O)—making it a zero-carbon fuel when produced via renewable energy sources (green hydrogen).

The combustion of hydrogen has sparked interest globally, especially as industries strive to meet net-zero targets. Hydrogen fuel in industrial heating is being explored for its potential to eliminate CO₂ emissions entirely from thermal processes.

Key Differences Between Hydrogen and Natural Gas Combustion

Here’s a comparative breakdown of Hydrogen Combustion vs. Natural Gas:

Feature | Natural Gas | Hydrogen |

Emissions | CO₂, NOx | Zero CO₂, low NOx |

Flame Temp. | Lower | Higher |

Energy Content | Moderate (per kg) | Higher per kg, lower per volume |

Infrastructure | Well-established | Developing |

Safety | Familiar protocols | Needs enhanced safety systems |

These distinctions emphasize the potential of hydrogen as a superior alternative for reducing emissions, though its practical challenges remain.

Industrial Implications of Switching to Hydrogen

Switching from natural gas to hydrogen is not a plug-and-play process. It involves:

- Retrofitting existing burners and furnaces

- Modifying burner controls to handle hydrogen’s faster flame speed

- Adapting safety systems for hydrogen leak detection

Encon Thermal Engineers is actively developing hydrogen burners for industry that are compatible with existing systems or can be custom-engineered. Our hydrogen-ready furnace solutions are designed to support your decarbonization journey with minimal disruption.

Environmental and Regulatory Pressures

Governments worldwide are enforcing stricter regulations on industrial emissions. From carbon taxes to emission trading systems, companies are now accountable for their carbon footprint.

Key Initiatives Driving the Shift:

- India’s National Hydrogen Mission

- EU’s Green Deal and Carbon Border Adjustment Mechanism

- US Inflation Reduction Act incentives

These frameworks make the Hydrogen vs Natural Gas emissions debate not just an environmental concern—but a business survival strategy.

Cost and Availability Considerations

While hydrogen offers clear environmental benefits, cost and availability are crucial decision-making factors.

Hydrogen:

- Green hydrogen (from renewables) is expensive due to electrolysis costs

- Grey hydrogen (from fossil fuels) emits CO₂ and undermines the climate goals

Natural Gas:

- Relatively affordable and widely available

- Subject to global price fluctuations and geopolitical risks

Governments are now offering incentives for hydrogen adoption, helping reduce the cost gap. However, mass-scale industrial adoption still hinges on economies of scale and infrastructure upgrades.

Challenges in Adopting Hydrogen Combustion

Despite its promise, hydrogen adoption faces several barriers:

- 🔒 Storage & Transport: Hydrogen molecules are small and require high-pressure storage or cryogenic systems.

- 🔧 Infrastructure Readiness: Limited pipeline networks and fueling stations.

- 🔥 Flame Detection Issues: Hydrogen flames are nearly invisible, requiring new detection technology.

- 🧯 Safety Protocols: Requires training and equipment adjustments for fire protection.

These challenges mean the shift won’t happen overnight—but preparation begins today.

The Future Outlook

The future of industrial combustion lies in hybrid models—blending hydrogen with natural gas to reduce emissions while ensuring performance stability. Over time, as technology matures, 100% hydrogen systems will become more common.

What’s Coming:

- R&D in low-NOx hydrogen burners

- Digital controls for real-time combustion tuning

- Expansion of hydrogen refueling and storage infrastructure

- Hydrogen hubs co-located with renewable energy sources

By 2025 and beyond, expect to see growing integration of hydrogen systems across steel, cement, glass, and chemical industries.

Why Encon is Leading the Transition

At Encon Thermal Engineers, we’re not just adapting to the hydrogen revolution—we’re helping shape it.

Why Choose Encon:

- Hydrogen-compatible burners and furnaces already in development and deployment

- Proven engineering expertise in clean combustion systems

- Support for decarbonization strategies, including ESCO-based energy saving models

- Focus on hydrogen-ready retrofits and scalable infrastructure

Whether you’re planning a greenfield project or upgrading an existing plant, Encon is your strategic partner for future-ready heating solutions.

Conclusion

The debate between Hydrogen Combustion vs. Natural Gas reflects a broader shift toward sustainability in industrial operations. While natural gas remains viable for the near term, hydrogen offers a carbon-free future with immense long-term potential.

As global emission targets tighten and fuel costs evolve, the importance of choosing the right fuel becomes a strategic imperative.

If you’re ready to future-proof your operations and lead in sustainability, now is the time to explore hydrogen-ready combustion systems.

📞 Contact Encon Thermal Engineers today to learn more about our custom solutions for clean, efficient, and future-ready industrial heating.