Introduction – The Need for Efficient Combustion in Oil and Gas The oil and gas industry plays a pivotal role in powering global economies. Yet, it faces mounting challenges: rising fuel costs, stringent emission regulations, and ambitious sustainability goals. Combustion efficiency has become a central focus for operators looking to optimize processes while minimizing costs […]

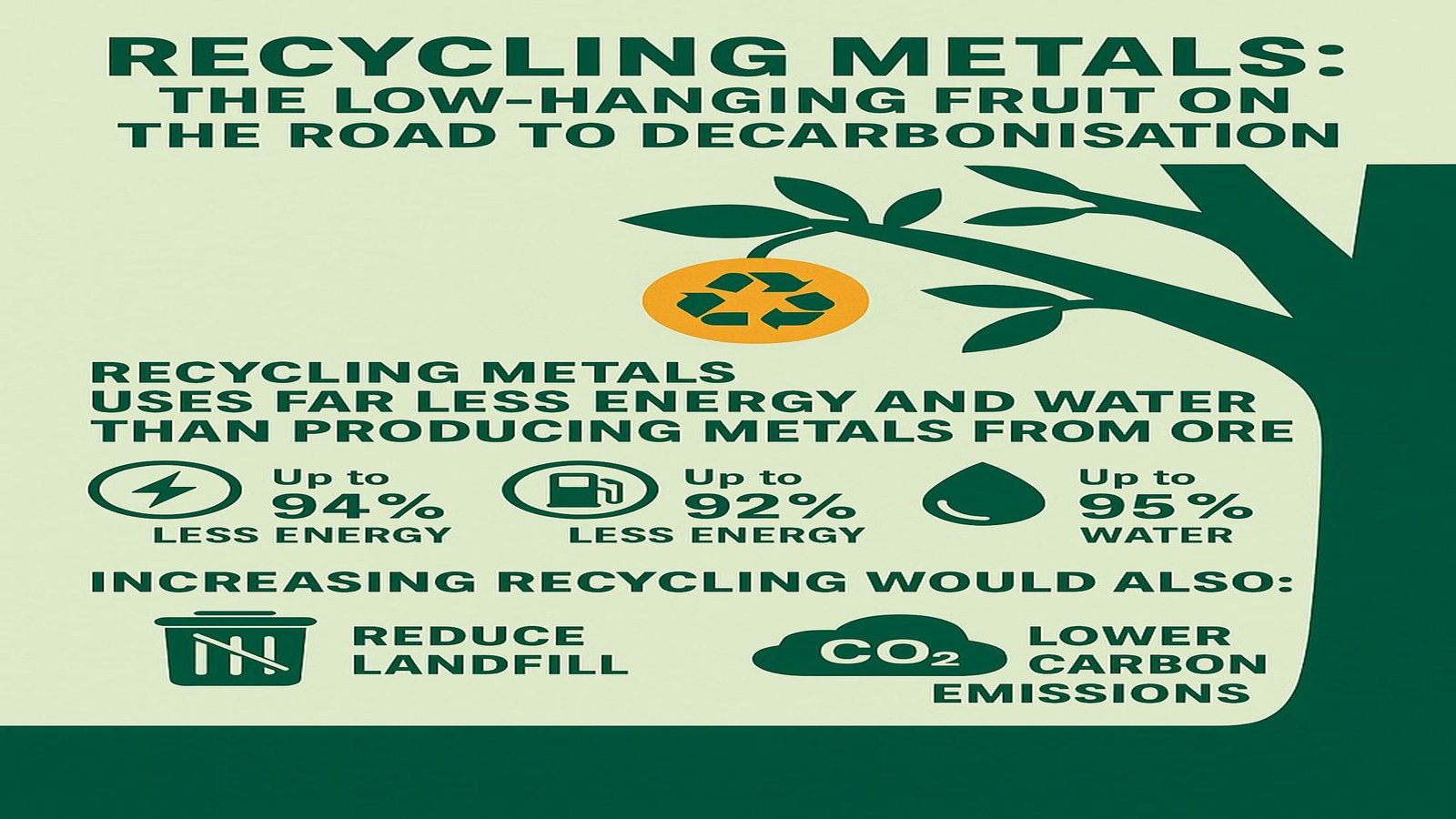

When conversations around decarbonisation, hydrogen, and clean technologies dominate the sustainability agenda, one powerful solution often remains underappreciated: recycling and decarbonisation. Recycling is not just about reusing materials; it is one of the most effective tools available to cut emissions, save water, reduce waste, and protect natural ecosystems. Yet despite overwhelming evidence, the industrial sector […]

India’s steel industry stands at the center of the nation’s decarbonisation challenge — and its opportunity. With the Government announcing a ₹5,000 crore National Mission for Sustainable Steel, the message is clear: the sector must become cleaner, greener, and globally competitive. This initiative is not just a policy announcement; it is a signal for transformation. […]

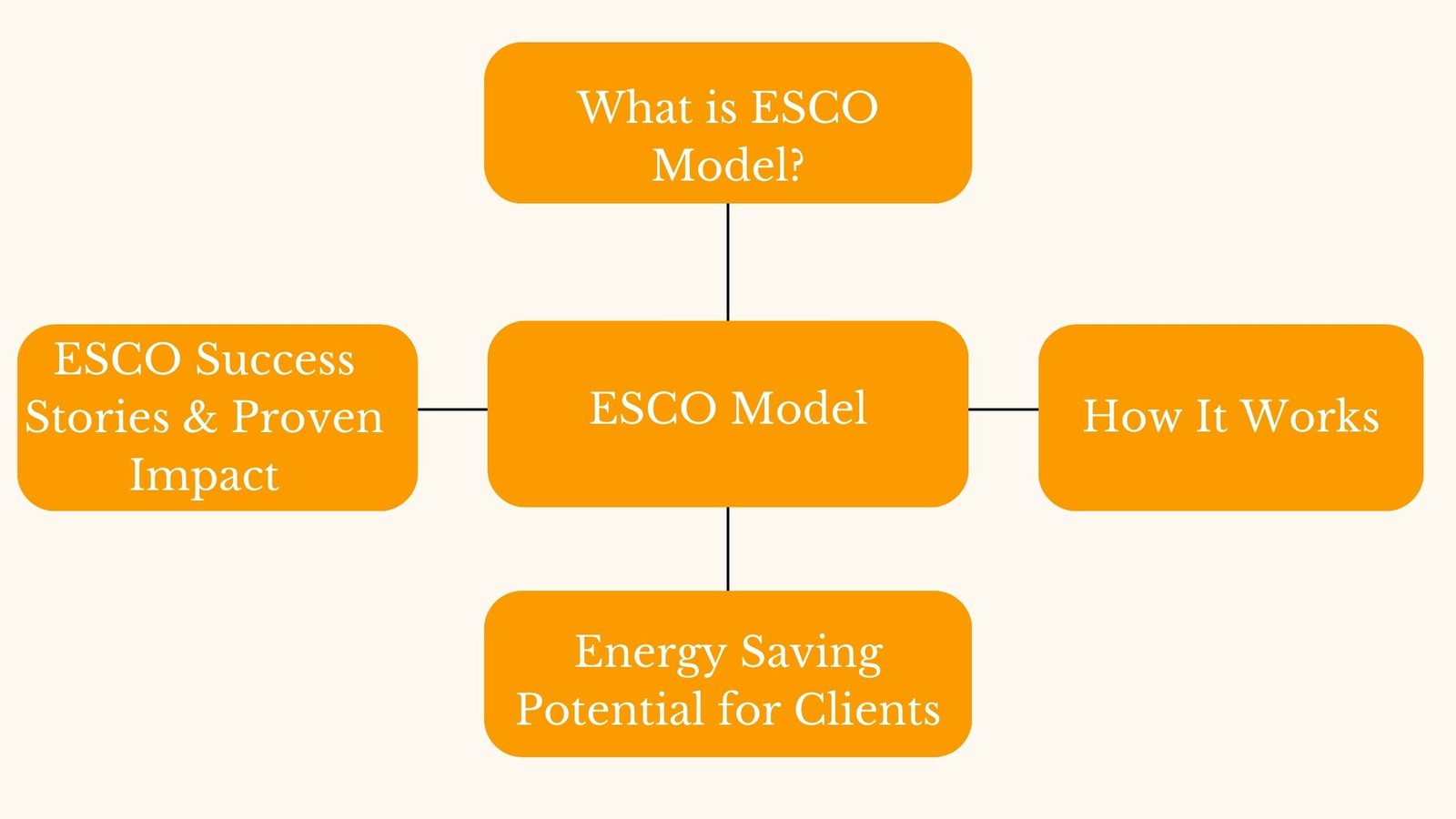

Driving Industrial Transformation: ENCON’s ESCO Model for Energy Efficiency In the face of rising fuel prices, environmental mandates, and increasing competition, industrial enterprises are under pressure to reduce energy costs and emissions—without compromising productivity. Enter the ESCO model, a revolutionary approach where energy efficiency becomes not just an operational goal, but a guaranteed outcome. At […]

🔥 Introduction: The Rising Concern of Industrial Emissions In today’s environmentally conscious industrial landscape, emission control has become more critical than ever. Among the most harmful pollutants from combustion processes are nitrogen oxides (NOx) and sulfur oxides (SOx), which contribute significantly to acid rain, smog, and respiratory issues. Industries relying on high-temperature processes—like steel, glass, […]

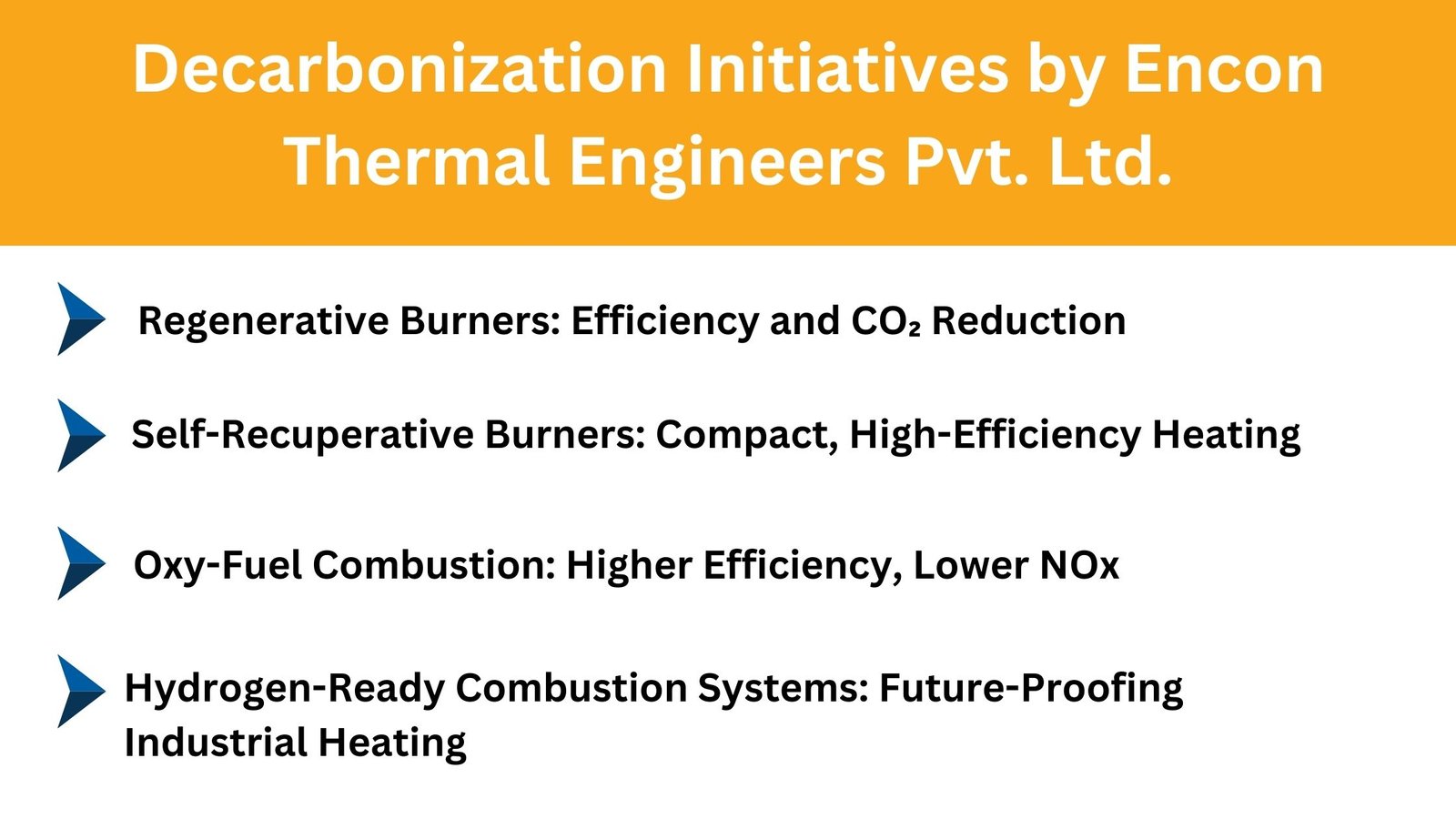

Driving Industrial Decarbonisation with Clean Thermal Technologies Industrial Decarbonisation: A Crucial Imperative for India With rising global temperatures and increasing environmental regulations, industrial decarbonisation has become essential for sustainable development. For energy-intensive sectors such as steel, forging, aluminium, and heat treatment, thermal processes contribute significantly to carbon emissions. Encon Thermal Engineers Pvt. Ltd. stands at […]

Introduction: Energy Efficiency – The Industrial Imperative In today’s competitive manufacturing environment, energy efficiency is no longer a choice—it’s a necessity. Rising fuel prices, stricter environmental norms, and the global push toward sustainability have compelled factories to rethink how they consume energy. But for many industrial units, especially in developing markets, implementing large-scale energy-saving projects […]

Introduction: Industrial Heating is Evolving—Fast In the world of manufacturing, energy efficiency and precision are no longer optional—they’re essential. As we step into 2025, the future of industrial heating is being redefined by technological innovation, environmental regulations, and the global push toward sustainability. From automotive to aerospace, food processing to pharmaceuticals, every sector relying on […]

Industries today face an urgent need to reduce energy consumption, lower carbon emissions, and enhance operational efficiency. However, many companies hesitate to adopt energy-saving technologies due to high upfront capital costs and uncertainties about returns. This is where the Energy Service Company (ESCO) model steps in as a game-changer. By providing zero-investment energy efficiency solutions, […]

As industries worldwide face increasing pressure to reduce carbon emissions, Encon Thermal Engineers Pvt. Ltd. has been at the forefront of developing and implementing advanced combustion solutions that drive efficiency while cutting CO₂ emissions. With over four decades of expertise in industrial heating solutions, Encon is committed to making industrial decarbonization not just a goal […]