Firstly, what are Regenerative Burners?

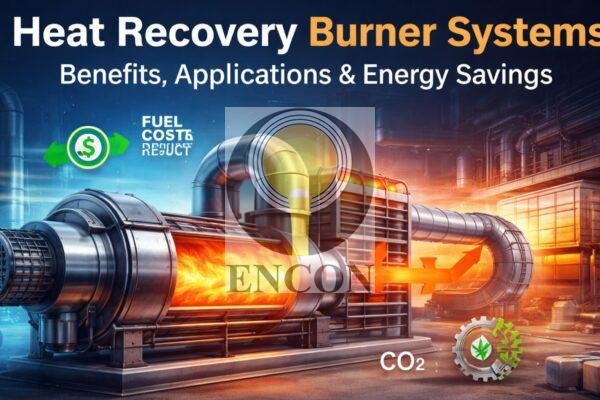

A regen burner is a combustion heating system that is designed for extremely high recovery of exhaust heat from an industrial furnace – The combustion air can be preheated to a temperature very close to the process temperature with the help of regenerator technology.

There are analyses regarding Regen burners that have found a 25-30% reduction in heating fuel consumption in a steel billet Reheating Furnace after ordinary burners with recuperators were replaced by Low NOx Regenerative Burners.

Regen burners usually operate in pairs and they work on the principle of short-term heat storage using ceramic heat regenerators.

Regen Burners recover between 85- 90% of the heat from the furnace waste gases; hence, the incoming combustion air can be preheated to very high temperatures of up to 10°- 150°C below the furnace operating temperature. The application temperatures swing from 800 up to 1500 °C and the fuel consumption can be reduced by up to 60%.

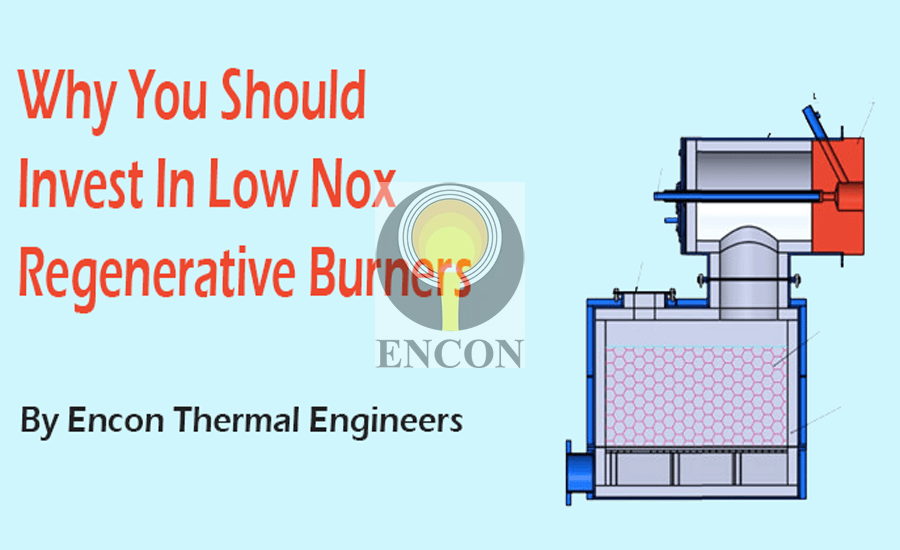

Then, let’s talk about regen burner design; BURNER Design: Each regenerative burner consists of the following main parts

1. Burner with Nozzles and burner Block

2. Regenerator box with Media Balls

3. LPG/NG Pilot burner with UV sensor and Ignition Transformer

We have basically designed the Regen burners for two modes of operations, Low NOx Flameless operation, and a normal flame operation.

The former mode of application can be selected for process temperatures higher than 800°C. The NOx emissions can range between 20 to 80% depending on the process temperature and parameters between the Normal and Low NOx flameless mode

Adding to all of it, some of the excellent advantages of Low NOx Regenerative Burners are:

1. Regen Burners allow excellent fuel savings.

2. Then is the trivial carbon footprint.

3. Regen Burners support fast heat transfer.

4. Regen Burners offer outstanding temperature uniformity.

5. Low NOx Regenerative Burners are easy to install.

6. Regen Burners are at a low cost.

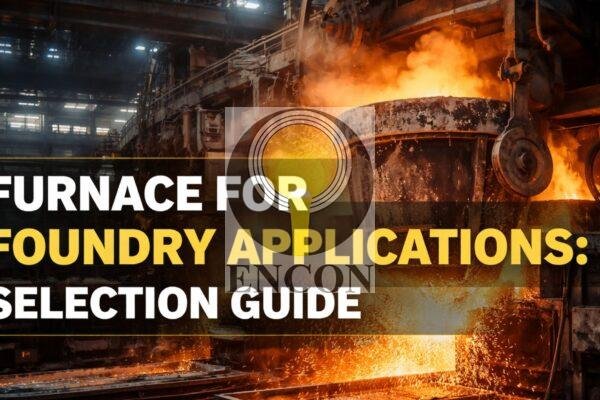

Low NOx Regenerative Burners are usually used for the following purposes:

1. Low NOx Regenerative Burners are used for Aluminium Melting.

2. Used for Forging.

3. Regen Burners are used for reheating.

4. For Hot Process Air Generation.

5. They are used for Glass Treatment.

6. Regen Burners are also used for Heat Treatment.

Encon Thermal Engineers has developed a range of Low NOx Regenerative Burners in association with Swiss Melting Technologies S.A.

Low NOx Regenerative Burner system has been specifically adapted and popularized in nearly high-temperature furnaces, which also includes reheating furnaces for rolling, forging furnaces, heat treatment furnaces, melting furnaces, baking furnaces, as a great means for saving cost energy and reducing CO2 emission.

Encon Thermal Engineers were judged as “WINNER for Innovation challenge 2019 for Waste Heat Recovery” by Facility for Low Carbon Technology Deployment (FLCTD) for their Regen Burners. Low NOx Regenerative burner provided by us can be used with various Gaseous fuels like LPG, Natural Gas, Producer Gas, Coke Oven Gas, Blast Furnace Gas, etc., and liquid fuels like Diesel, LDO, HFO, FO, pyrolysis oil, etc. We also offer Multiple fuel options in the same Regen burner.

Encon Thermal Engineers work towards customer satisfaction and we assure to provide you with excellent products and services.