Driving Industrial Transformation: ENCON’s ESCO Model for Energy Efficiency

In the face of rising fuel prices, environmental mandates, and increasing competition, industrial enterprises are under pressure to reduce energy costs and emissions—without compromising productivity.

Enter the ESCO model, a revolutionary approach where energy efficiency becomes not just an operational goal, but a guaranteed outcome.

At ENCON Thermal Engineers Pvt. Ltd., we’re proud to be at the forefront of this transformation, helping industries save up to 40% in fuel costs, reduce CO₂ emissions by up to 60%, and achieve payback within 9–12 months—all without upfront capital investment.

💡 What Is an ESCO?

An Energy Service Company (ESCO) implements energy-saving technologies and solutions at zero capital cost to the client. The project is funded through the actual savings generated, making it a risk-free, performance-based model.

ENCON brings this model to life in the thermal and combustion domain, serving industries that rely on heat-intensive processes and equipment such as furnaces, kilns, and preheaters. To explore how this model is already transforming energy usage across industries, check out our case-driven ESCO solutions here.

🚀 Why Choose ENCON’s ESCO Model?

With decades of experience in combustion engineering, ENCON offers a comprehensive ESCO approach that is:

✅ Zero CapEx

We finance the entire project, removing the upfront investment barrier.

✅ Guaranteed Savings

Clients pay only when savings are verified, ensuring a performance-linked contract.

✅ Rapid Payback

Most projects break even within 9–12 months.

✅ Advanced Technologies

We deploy regenerative burners, self-recuperative burners, oxy-fuel systems, flue gas heat recovery, and even hydrogen-ready combustion.

✅ Sustainability-Aligned

With up to 60% CO₂ reduction, our ESCO solutions support decarbonization goals and ESG compliance.

✅ End-to-End Management

From audits and engineering to execution and M&V, ENCON manages the complete lifecycle.

🔧 Technologies We Deploy

ENCON’s ESCO solutions are built around cutting-edge combustion and heat recovery technologies:

Regenerative Burners

Reuse exhaust heat to achieve energy savings of 30–40%.

Self-Recuperative Burners

Built-in heat exchangers for localized thermal efficiency.

Oxy-Fuel Combustion

Removes nitrogen from the equation, reducing NOx and fuel use.

Hydrogen Combustion

Ready for future zero-carbon fuels.

Flue Gas Heat Recovery Systems

Capture and recycle waste heat for process optimization.

🏭 Industries We Serve

Our ESCO model is ideal for energy-intensive sectors such as:

- Steel Plants & Rolling Mills

- Forging Units

- Reheating Furnaces

- Aluminum Melting Plants

- Heat Treatment Shops

- Foundries & Kilns

If your business relies on high-temperature thermal processes, ENCON’s ESCO model can unlock guaranteed energy savings and compliance benefits.

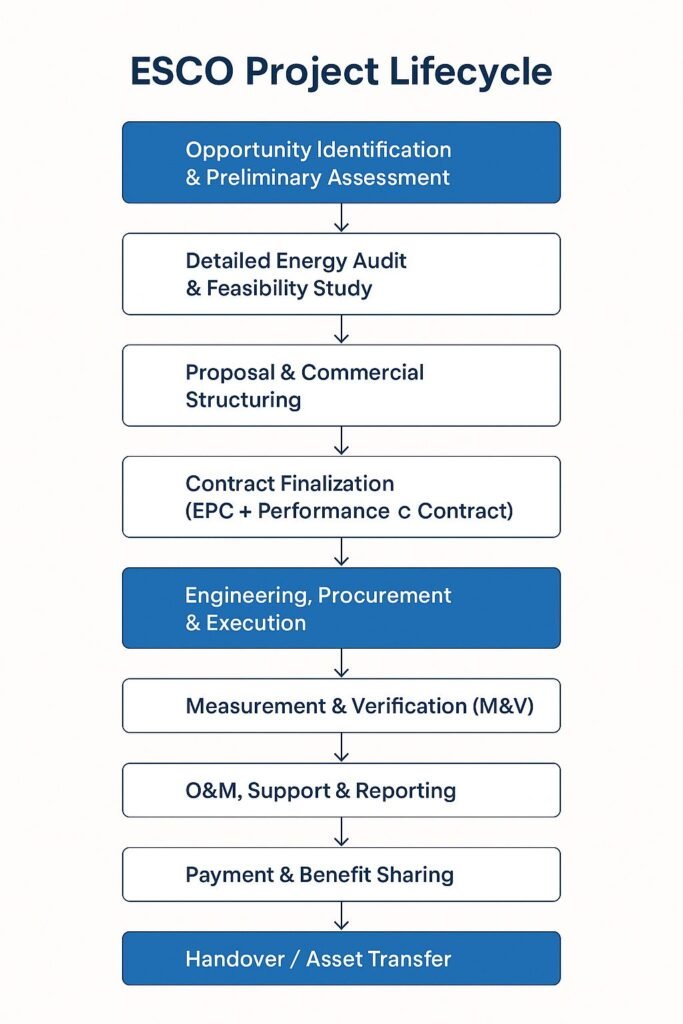

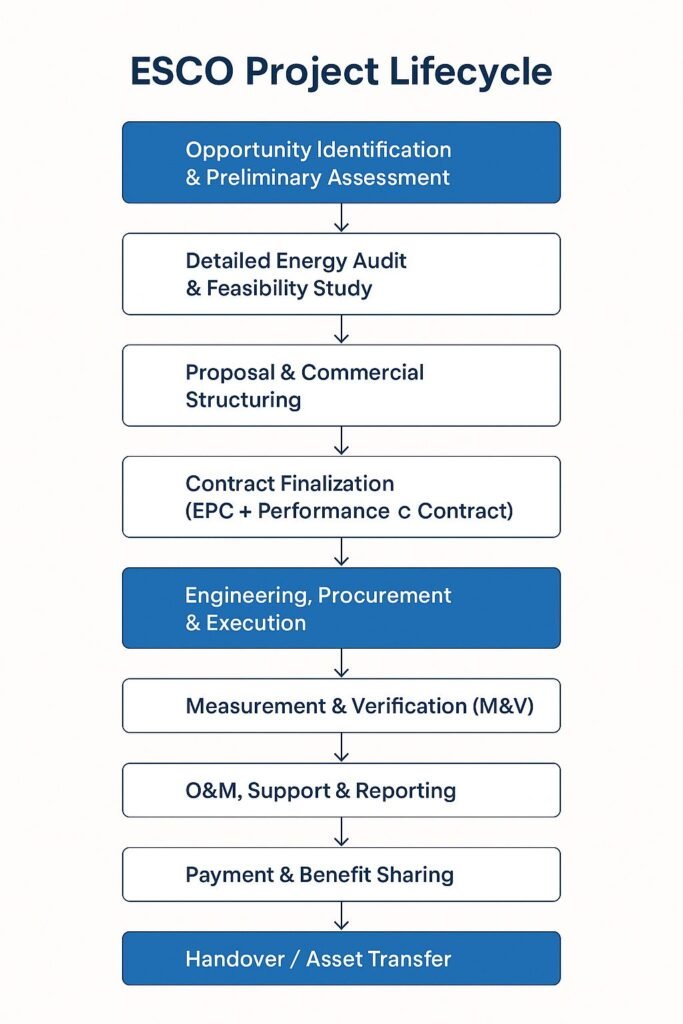

🧭 ENCON’s 10-Step ESCO Project Lifecycle

We don’t just deliver equipment—we deliver outcomes. Here’s how we ensure success at every stage:

1. Opportunity Identification

Audit and assess the client’s baseline and ESCO feasibility.

2. Detailed Energy Audit

Conduct thermal analysis, design modeling, and ROI projections.

3. Proposal & Structuring

Offer performance-guaranteed savings models and draft legal frameworks.

4. Contract Finalization

Define EPC and savings-based contract structure.

5. Engineering & Execution

End-to-end thermal system design, fabrication, and site integration.

6. Measurement & Verification (M&V)

Use IPMVP-compliant methods and real-time data to verify savings.

7. O&M and Support

Optional maintenance and reporting to ensure continued performance.

8. Payment & Benefit Sharing

Pay-as-you-save model, with optional carbon credit monetization.

9. Handover / Asset Transfer

Equipment handed over to client at contract end—usually at zero cost.

10. Post-Contract Support

AMC, scale-up opportunities, and ongoing emissions monitoring.

🌍 Why ESCO is the Future of Industrial Decarbonization

The industrial sector accounts for a major share of energy consumption and CO₂ emissions globally. With tightening regulations and growing sustainability expectations, energy efficiency is no longer optional—it’s a strategic imperative.

ENCON’s ESCO model empowers industries to:

- Cut costs without CapEx

- Meet carbon reduction targets

- Improve process efficiency

- Monetize carbon credits

- Future-proof against energy risks

🤝 Partner with ENCON for a Greener, More Profitable Future

Whether you’re running a steel mill, foundry, forging shop, or aluminum melting unit, ENCON can deliver up to 40% energy savings through proven, performance-based solutions.

We’re not just your vendor—we’re your energy efficiency partner.

📞 Let’s start a conversation today to assess your potential savings.

🌐 Visit: www.encon.co.in

📩 Email: info@encon.co.in