Industries today are constantly seeking ways to become more efficient, and a key focus area is energy cost reduction. By implementing customized heat recovery solutions, companies can capture waste heat and reuse it, helping them save energy and cut operating costs. This not only reduces expenses but also helps lessen their environmental impact. At Encon Thermal Engineers, we specialize in creating customized solutions that enable industries to maximize efficiency and minimize waste.

What Exactly Are Heat Recovery Solutions?

Heat recovery solutions involve capturing heat that would otherwise be wasted during various industrial processes. This could be heat generated from exhaust gases, cooling systems, or other sources where energy is typically lost. By recovering and repurposing this waste heat, businesses reduce the need for additional energy, leading to significant energy cost reduction.

For example, consider a manufacturing plant where exhaust gases are released into the atmosphere. With a heat recovery system in place, this waste heat can be captured using heat exchangers or other specialized equipment. The recovered heat can then be reused for preheating materials, space heating, or steam generation. This process not only conserves energy but also enhances overall operational efficiency.

Why Go for Customized Heat Recovery Solutions?

While heat recovery systems are not a new concept, the need for customized heat recovery solutions has grown due to the unique nature of every industrial setup. What works for one facility may not work for another, and customization allows companies to tailor systems to their specific processes.

At Encon Thermal Engineers, we recognize that each industry has its own set of challenges. That’s why we focus on developing tailored solutions that cater to each client’s specific needs. By designing systems that target particular waste heat sources, we ensure that businesses achieve optimal energy savings and energy cost reductions. Whether it’s heat from furnaces, boilers, or other industrial equipment, a custom-designed system ensures maximum efficiency and a strong return on investment.

Benefits of Implementing Heat Recovery Systems

- Reduced Energy Costs: One of the most significant advantages of heat recovery systems is energy cost reduction. Capturing and reusing waste heat reduces the need for additional energy, directly impacting your bottom line. Studies show that heat recovery systems can save between 5% and 30% of energy consumption, depending on the industry and application.

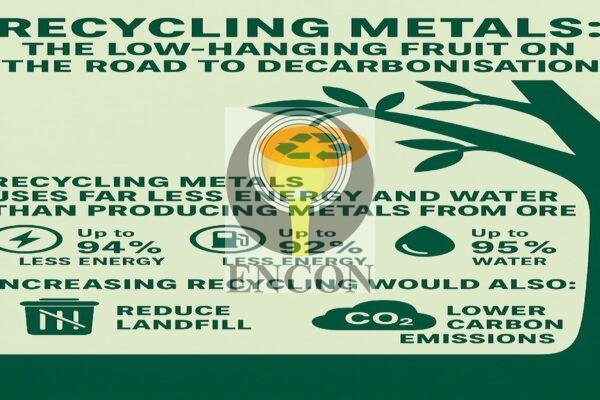

- Environmental Impact: Beyond cost savings, heat recovery systems help reduce a company’s carbon footprint. By repurposing waste heat, industries reduce their reliance on fossil fuels, which in turn lowers greenhouse gas emissions. This contributes to more sustainable practices and helps businesses comply with environmental regulations.

- Increased Operational Efficiency: Having a customized heat recovery system allows industries to improve their operational efficiency. Instead of letting valuable heat escape into the environment, businesses can capture and reuse it, resulting in more stable energy supplies and smoother operations.

- Return on Investment (ROI): Although implementing a heat recovery system requires an initial investment, long-term savings on energy costs result in a favorable return on investment. Many companies see a rapid ROI, with ongoing energy savings that add to their profitability.

Industries That Benefit the Most

Numerous industries benefit from customized heat recovery solutions, particularly those with energy-intensive processes where waste heat is generated in significant amounts. These industries include:

- Manufacturing: Industries like metalworking, where processes such as smelting or casting generate substantial waste heat, are ideal candidates for heat recovery. By capturing and reusing this heat, manufacturers can significantly lower energy costs.

- Food and Beverage: Heat plays a major role in food processing and beverage production. Implementing heat recovery systems allows these industries to reduce energy consumption, improve operational efficiency, and lower costs.

- Chemical Processing: Chemical plants often rely on high-temperature processes that generate large amounts of waste heat. Recovering this heat can help reduce energy consumption and create more sustainable production practices.

- Power Generation: Power plants that rely on fossil fuels can use heat recovery systems to improve thermal efficiency, reducing fuel consumption and operating costs.

How Encon Thermal Engineers Can Help

At Encon Thermal Engineers, we take a systematic approach to customized heat recovery solutions. Here’s how we do it:

- Heat Audit: We begin by conducting a comprehensive heat audit of your facility. This involves identifying waste heat sources and determining how much recoverable heat is available.

- System Design: Based on the audit, we design a customized system tailored to your facility’s specific needs. This ensures the system will operate efficiently and provide maximum energy savings.

- Seamless Installation: After the design phase, our team handles the installation, ensuring that the heat recovery system integrates seamlessly with your existing infrastructure, minimizing operational disruptions.

- Maintenance and Monitoring: To keep the system running optimally, we offer maintenance and monitoring services. Regular maintenance ensures that your system continues to deliver optimal energy savings and operational efficiency.

The Future of Heat Recovery

As energy efficiency and sustainability continue to gain importance in the business world, heat recovery technologies are evolving to meet these needs. Technological advancements are enabling businesses to recover even more waste heat, further reducing energy consumption and operating costs.

In the future, customized heat recovery systems are expected to become more intelligent. The integration of IoT (Internet of Things) and smart technologies will allow for real-time monitoring, predictive maintenance, and improved performance, ensuring that businesses stay ahead in energy efficiency.

Conclusion

Implementing customized heat recovery solutions is a smart move for industries looking to improve efficiency and reduce costs. Not only do these systems contribute to energy cost reduction, but they also support more sustainable and environmentally friendly business models. At Encon Thermal Engineers, we’re dedicated to helping industries harness the power of waste heat and turn it into a valuable resource.

By opting for a customized solution, you’re not just enhancing efficiency—you’re making a long-term commitment to reducing energy consumption and creating a more sustainable future for your business. Let us guide you through that process with our expertise and innovative solutions. Contact us today for a customized consultation.