In industrial manufacturing, where high temperatures are crucial for processes such as metalworking, ceramics production, and chemical reactions, industrial furnaces play a central role. However, maintaining optimal thermal efficiency in these furnaces is essential not only for performance but also for reducing energy consumption and operating costs. One of the most effective ways to improve thermal efficiency is by employing high-quality refractory materials in industrial furnaces.

At Encon Thermal Engineers, we specialize in designing and building industrial furnaces that optimize thermal efficiency through advanced refractory materials and insulation techniques. In this blog, we will explore the benefits of using refractory materials, discuss various insulation techniques, and highlight how these strategies can significantly enhance overall efficiency.

What Are Refractory Materials?

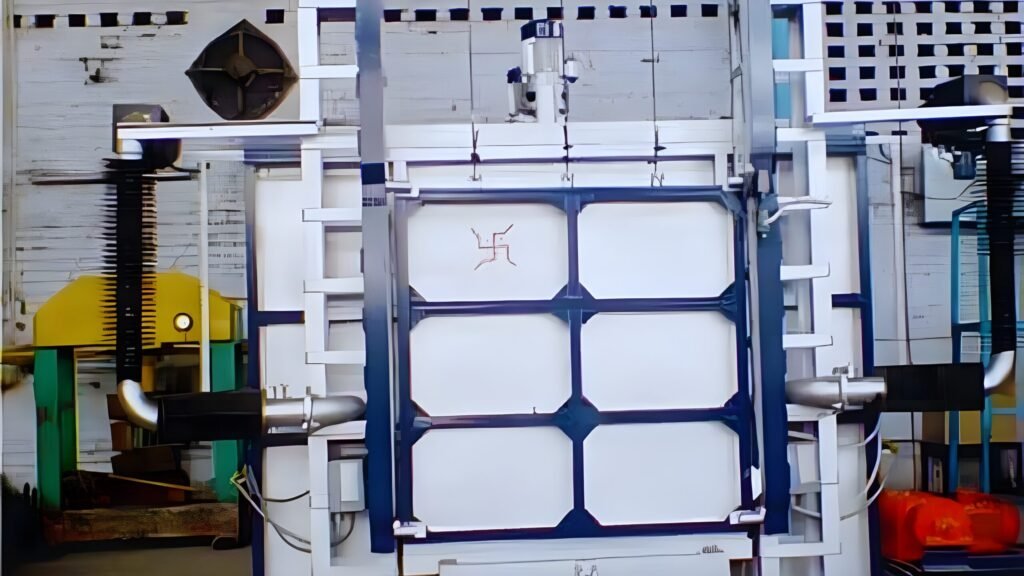

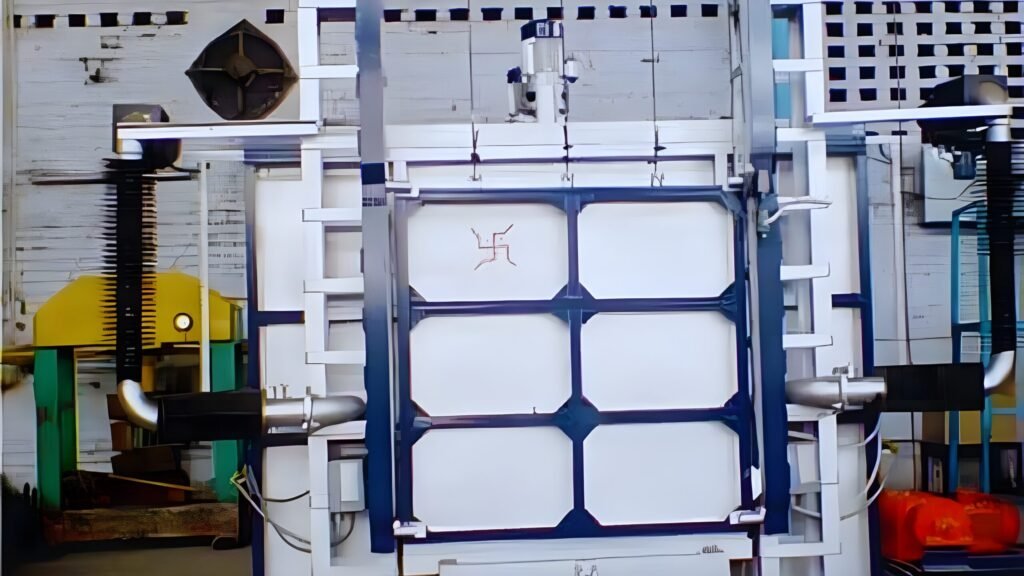

Refractory materials are heat-resistant substances used to line industrial furnaces, kilns, and reactors that operate at extremely high temperatures. These materials are designed to withstand extreme heat, thermal shock, abrasion, and chemical corrosion, making them indispensable for high-temperature industrial applications. Common refractory materials include:

- Firebricks: Dense bricks with excellent heat retention, commonly used in furnaces and kilns.

- Ceramic fibers: Lightweight and flexible materials that provide excellent insulation.

- Castables and ramming masses: Cement-like materials used to line and repair furnace interiors.

- Insulating bricks: Lightweight, porous bricks that offer effective thermal insulation while reducing the overall weight of the furnace.

The selection of refractory materials for industrial furnaces depends on specific temperature ranges and environmental conditions. For instance, ceramic fibers are preferred in furnace requiring quick heating and cooling cycles, while firebricks are ideal for applications demanding prolonged exposure to high temperatures.

How Refractory Materials Enhance Thermal Efficiency

Achieving and maintaining high thermal efficiency in industrial furnaces requires more than just selecting the right refractory materials. Effective industrial furnace insulation techniques play a crucial role in minimizing heat loss, reducing energy consumption, and improving operational efficiency. Here are some common techniques used in Encon Thermal Engineers’ industrial furnaces:

- Layered Insulation Design: Layered insulation involves applying multiple layers of refractory materials with varying properties to maximize heat retention. This multi-layered approach ensures that the furnace maintains a consistent temperature while reducing the energy required to maintain it.

- Proper Sealing of Joints and Gaps: Poorly sealed joints and gaps can cause significant heat loss. Encon’s furnaces utilize high-temperature-resistant seals to trap heat, preventing energy loss and maintaining optimal temperatures.

- Installation of Insulating Boards: Insulating boards, made from materials like vermiculite or calcium silicate, prevent the transfer of heat from the oven chamber to its outer shell, improving insulation performance.

- Reflective Insulation: Reflective insulation materials help reduce heat loss by reflecting radiant heat back into the furnace chamber. This enhances thermal efficiency and decreases energy consumption.

The Importance of Industrial Furnace Insulation Techniques

At Encon Thermal Engineers, we understand that the selection and application of refractory materials directly impact the thermal efficiency of industrial furnaces. Here’s how these materials contribute to improving thermal efficiency:

- Layered Insulation Design: Layered insulation involves applying multiple layers of refractory materials with varying properties to maximize heat retention. This multi-layered approach ensures that the furnace maintains a consistent temperature while reducing the energy required to maintain it.

- Proper Sealing of Joints and Gaps: Poorly sealed joints and gaps can cause significant heat loss. Encon’s furnaces utilize high-temperature-resistant seals to trap heat, preventing energy loss and maintaining optimal temperatures.

- Installation of Insulating Boards: Insulating boards, made from materials like vermiculite or calcium silicate, prevent the transfer of heat from the furnace chamber to its outer shell, improving insulation performance.

- Reflective Insulation: Reflective insulation materials help reduce heat loss by reflecting radiant heat back into the furnace chamber. This enhances thermal efficiency and decreases energy consumption.

How Refractory Materials Enhance Thermal Efficiency

At Encon Thermal Engineers, we understand that the selection and application of refractory materials directly impact the thermal efficiency of industrial furnaces. Here’s how these materials contribute to improving thermal efficiency:

- Minimizing Heat Loss: By using materials like ceramic fibers and insulating bricks with low thermal conductivity, we ensure heat is contained, reducing the need for constant reheating.

- Enhancing Heat Retention: Refractory materials help furnaces maintain their target temperature for extended periods, reducing energy requirements.

- Withstanding Thermal Shock: Our furnaces are designed to handle rapid temperature changes, ensuring durability and optimal efficiency during demanding thermal cycles.

- Reducing Maintenance and Downtime: High-quality refractory linings improve durability, minimizing maintenance and repair needs, leading to reduced downtime and lower operational costs.

The Future of Thermal Efficiency in Industrial Furnaces

As the demand for energy efficiency continues to grow, Encon Thermal Engineers remains at the forefront of innovation by incorporating the latest refractory materials and advanced insulation techniques. Our industrial furnaces reduce energy consumption and enhance productivity and sustainability.

For more details on how we can help optimize your industrial furnaces thermal efficiency, visit our Furnaces Page to explore our range of customized solutions.

Conclusion

Optimizing thermal efficiency in industrial furnaces is essential for reducing energy consumption, lowering operating costs, and ensuring the longevity of equipment. At Encon Thermal Engineers, we provide advanced solutions that combine the best refractory materials for industrial furnaces with innovative industrial furnace insulation techniques to deliver superior performance. Contact us today to discover how we can help you enhance your production processes and reduce energy costs.