Regenerative burners are an important technology used in industrial heating applications. These burners are known for their energy efficiency and environmental benefits, making them a popular choice for industrial operations worldwide. In this article, we will explore what regenerative burners are, how they work, and their benefits for industrial heating.

What are Regenerative Burners?

Regenerative burners are industrial burners that use a heat storage system to recover and reuse waste heat. These burners use two burners, one of which is active and the other which is regenerating. The active burner burns fuel and air, producing heat that is transferred to the material being heated. The exhaust gases are then directed to the regenerating burner, which stores the heat in a ceramic media bed. The regenerating burner uses this stored heat to preheat the combustion air before it enters the active burner.

How do Regenerative Burners Work?

Regenerative burners work by using a heat storage system to recover and reuse waste heat. The active burner burns fuel and air, producing heat that is transferred to the material being heated. The exhaust gases are then directed to the regenerating burner, which stores the heat in a ceramic media bed. The regenerating burner uses this stored heat to preheat the combustion air before it enters the active burner.

The heat storage system allows for efficient heat transfer between the exhaust gases and the incoming combustion air. This results in higher efficiency and lower fuel consumption compared to traditional burners. Additionally, regenerative burners produce fewer harmful emissions, making them an environmentally friendly option.

Benefits of Regenerative Burners

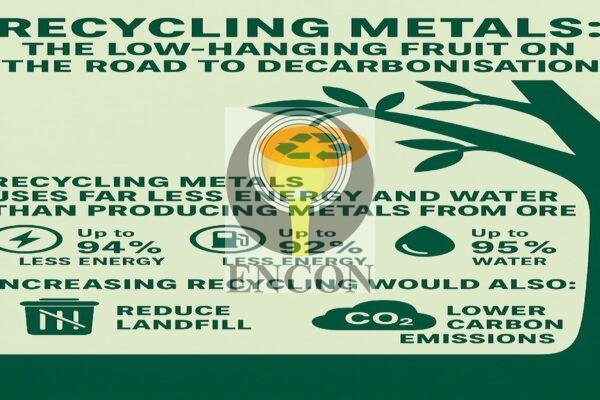

Regenerative burners have several benefits for industrial heating applications. Firstly, they are energy efficient and can reduce fuel consumption by up to 50%. This translates to significant cost savings over time. Secondly, regenerative burners produce fewer emissions than traditional burners, which helps to reduce the carbon footprint of industrial operations. This is particularly important for industries that need to comply with strict environmental regulations.

Another benefit of regenerative burners is their ability to provide consistent heating. The heat storage system ensures that the incoming combustion air is consistently preheated, which helps to maintain a constant temperature in the heating process. This is important for industries that require precise temperature control, such as glass manufacturing and semiconductor production.

Applications of Regenerative Burners

Regenerative burners are used in a wide range of industrial heating applications. They are particularly popular in the glass manufacturing industry, where they are used to melt glass and maintain a constant temperature during the melting process. They are also used in industries such as food processing, ceramic production, and metalworking.

Conclusion

Regenerative burners are a cost-effective and environmentally friendly option for industrial heating applications. Their ability to recover and reuse waste heat results in significant energy savings and reduced emissions. With their consistent heating capabilities and the broad range of applications, regenerative burners are an attractive option for industries looking to improve their efficiency, reduce their carbon footprint, and increase their profitability.

Ready to Maximize Your Energy Savings?

Looking to boost furnace efficiency, cut fuel costs, and reduce your carbon footprint with advanced regenerative burner technology? Our team at ENCON Thermal Engineers can help you find the right solution tailored to your industrial needs.

👉 Contact us today to discuss your application and get a customized proposal.

📩 Email us at sales@encon.co.in

📞 Call us at +91-98715 90093