When conversations around decarbonisation, hydrogen, and clean technologies dominate the sustainability agenda, one powerful solution often remains underappreciated: recycling and decarbonisation.

Recycling is not just about reusing materials; it is one of the most effective tools available to cut emissions, save water, reduce waste, and protect natural ecosystems. Yet despite overwhelming evidence, the industrial sector continues to lean heavily on virgin metal production.

Why is recycling not promoted as aggressively as it should be? Why do manufacturers often prefer fresh extraction, even though recycled materials perform equally well? And why isn’t recycling at the heart of climate and industrial strategies worldwide?

It’s time we looked at the facts.

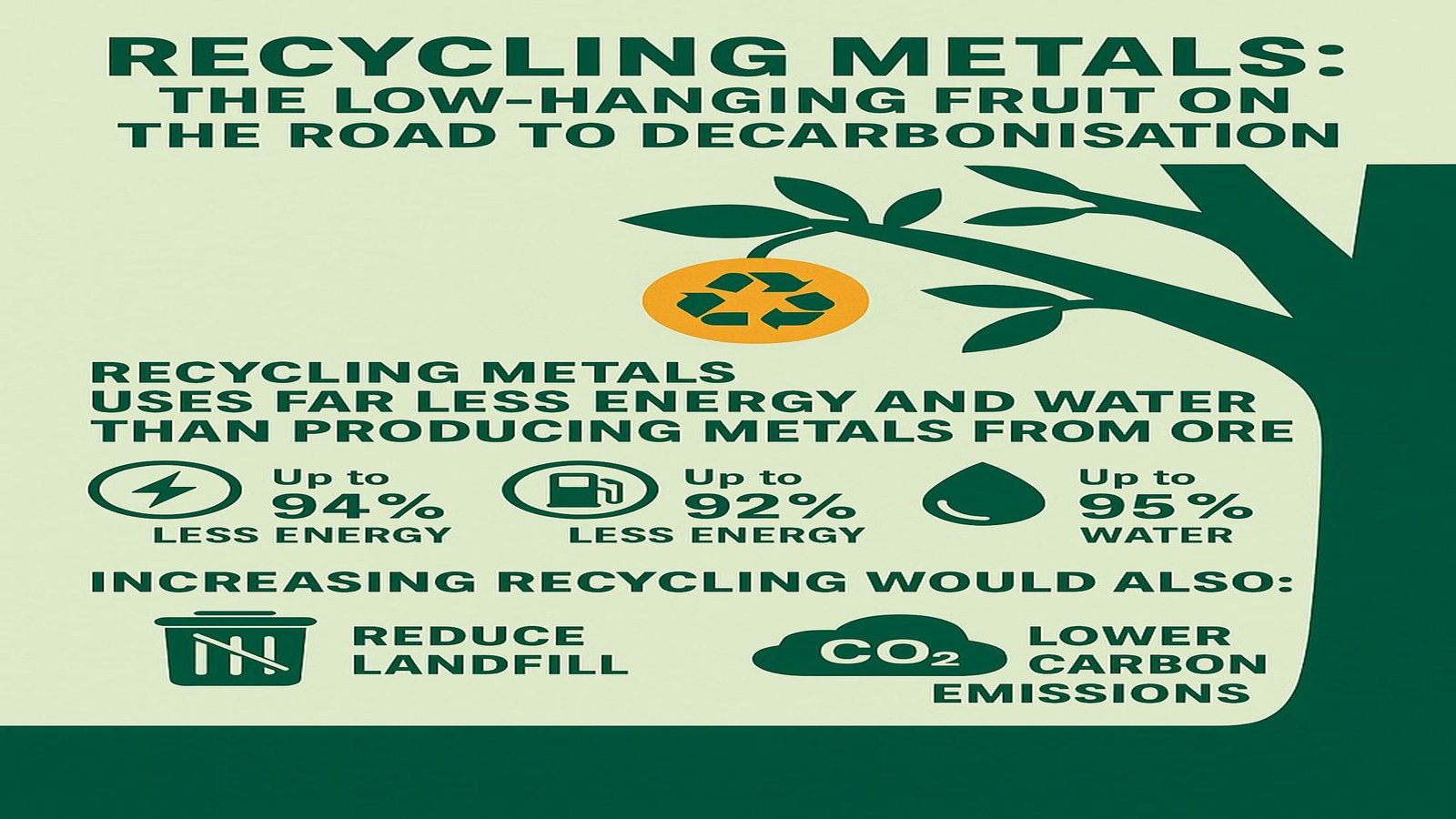

The Evidence: Recycling Saves Energy, Emissions, and Resources

The numbers are undeniable. Metal recycling for emission reduction delivers dramatic environmental benefits compared to ore-based production:

- Aluminium recycling saves ~95% of the energy compared to virgin production 【aluminum.org】

- Steel recycling cuts CO₂ emissions by ~58% and reduces water use by ~40% 【euric.eu】

- Copper recycling saves ~65% of emissions 【stenarecycling.com】

- Lithium recycling reduces water use by more than 99% compared to brine extraction 【drawdown.org】

- Globally, expanding recycling could prevent 4–12 gigatons of CO₂-equivalent emissions by 2050 【drawdown.org】

These statistics highlight that sustainable industrial recycling is not a marginal practice—it is a climate imperative. When combined with water savings, reduced land use, and lower dependence on mining, the potential becomes even more mind-boggling.

Recycling: More Than Just Emissions Savings

Recycling is about much more than energy and carbon. It represents a systemic shift toward a circular economy through recycling, where materials are looped back into industrial cycles rather than discarded.

Some of the broader benefits include:

- Less landfill: Reducing the burden on waste management systems

- Less mining: Minimising deforestation, soil erosion, and biodiversity loss

- Lower energy bills: Cutting industrial fuel costs while enhancing competitiveness

- Resource preservation: Extending the life of scarce minerals and metals

In short, recycling is both an environmental and economic opportunity that contributes directly to industrial decarbonisation.

Why Recycling Isn’t Getting Enough Attention

Despite the clear advantages, recycled metals are still underutilised. A few reasons why:

- Market inertia – Manufacturers often stick to virgin production methods out of habit or fear of inconsistency.

- Policy gaps – Lack of strong government incentives, subsidies, or procurement rules favouring recycled content.

- Perception issues – A false belief that recycled metals are inferior, despite evidence of comparable performance.

- Initial costs – While recycling systems are efficient in the long run, upgrading infrastructure requires investment.

Addressing these challenges requires policy action, corporate responsibility, and technology upgrades that make energy-efficient recycling technologies even more viable.

ENCON’s Role: Making Recycling Energy-Efficient

Recycling itself still consumes energy—especially in processes like melting, re-melting, and thermal treatment. This is where ENCON Thermal Engineers Pvt. Ltd. comes in.

For over four decades, ENCON has been innovating industrial heating technologies designed for efficiency, conservation, and clean combustion. By integrating advanced thermal solutions into recycling plants, ENCON ensures that the recycling process maximises environmental benefits without shifting the burden back onto fuel consumption.

Key technologies include:

🔹 Regenerative Burners

Recovering waste heat from flue gases to preheat combustion air, reducing fuel use and supporting waste heat recovery in recycling plants.

🔹 Self-Recuperative Burners

Compact burners with integrated heat exchangers for on-site energy recovery.

🔹 Oxy-Fuel Systems

Achieving cleaner combustion with lower nitrogen oxide (NOx) emissions.

🔹 Hydrogen-Ready Solutions

Preparing industries for the next generation of hydrogen-ready recycling technologies and zero-carbon fuels.

With these ENCON energy-efficient solutions, industries can cut energy bills, carbon emissions, and operational costs while making recycling truly sustainable.

Recycling + Clean Technology = A Circular Future

Imagine a future where every ton of aluminium, steel, copper, or lithium re-enters the industrial cycle with minimal energy cost. A future where recycling and clean combustion systems make metal recovery nearly emission-free.

That is the vision of the circular economy through recycling, and it is not far-fetched—it is possible today with the right mix of policy, industry action, and technology.

Conclusion: The Time to Scale Recycling is Now

The evidence is clear:

- Recycling slashes emissions.

- Recycling conserves water and land.

- Recycling reduces industrial costs.

- And with ENCON’s solutions, recycling itself becomes even cleaner and more efficient.

The question is no longer whether recycling works—it is why we are not scaling it faster.

If industries, policymakers, and innovators join forces, recycling and decarbonisation can become the cornerstone of global sustainability strategies. And companies like ENCON are ready to power that transition.

✦ Ready to make your recycling process more efficient and sustainable?

Connect with ENCON Thermal Engineers Pvt. Ltd. to explore advanced heating and combustion solutions that enable a true circular economy through recycling.