🔥 Introduction: The Hidden Cost of Furnace Operation

Industrial furnaces are the workhorses of sectors like steel, glass, ceramics, aluminum, and petrochemicals. However, one of the major challenges in furnace operation is refractory wear—a silent yet significant factor affecting operational costs, energy efficiency, and production downtime.

The integration of Oxy-Fuel Refractory Protection has emerged as a breakthrough solution to prolong furnace life and reduce maintenance frequency. This blog explores how advanced oxy-fuel combustion systems are now engineered not only for emissions control but also for reducing refractory damage with oxy-fuel burners.

🧱 What Is Furnace Refractory and Why Is It Important?

Refractory materials form the lining of high-temperature industrial furnaces, acting as a thermal shield that retains heat while withstanding harsh chemical, thermal, and mechanical stress.

Problems arise when these linings erode or crack due to:

- Direct flame impingement

- Chemical attack from combustion byproducts

- Thermal cycling and hot spots

- Poor combustion control or uneven heat distribution

Without adequate protection, refractory failure leads to:

- High repair costs

- Extended downtimes

- Loss in thermal efficiency

- Safety hazards

🔬 What is Oxy-Fuel Refractory Protection?

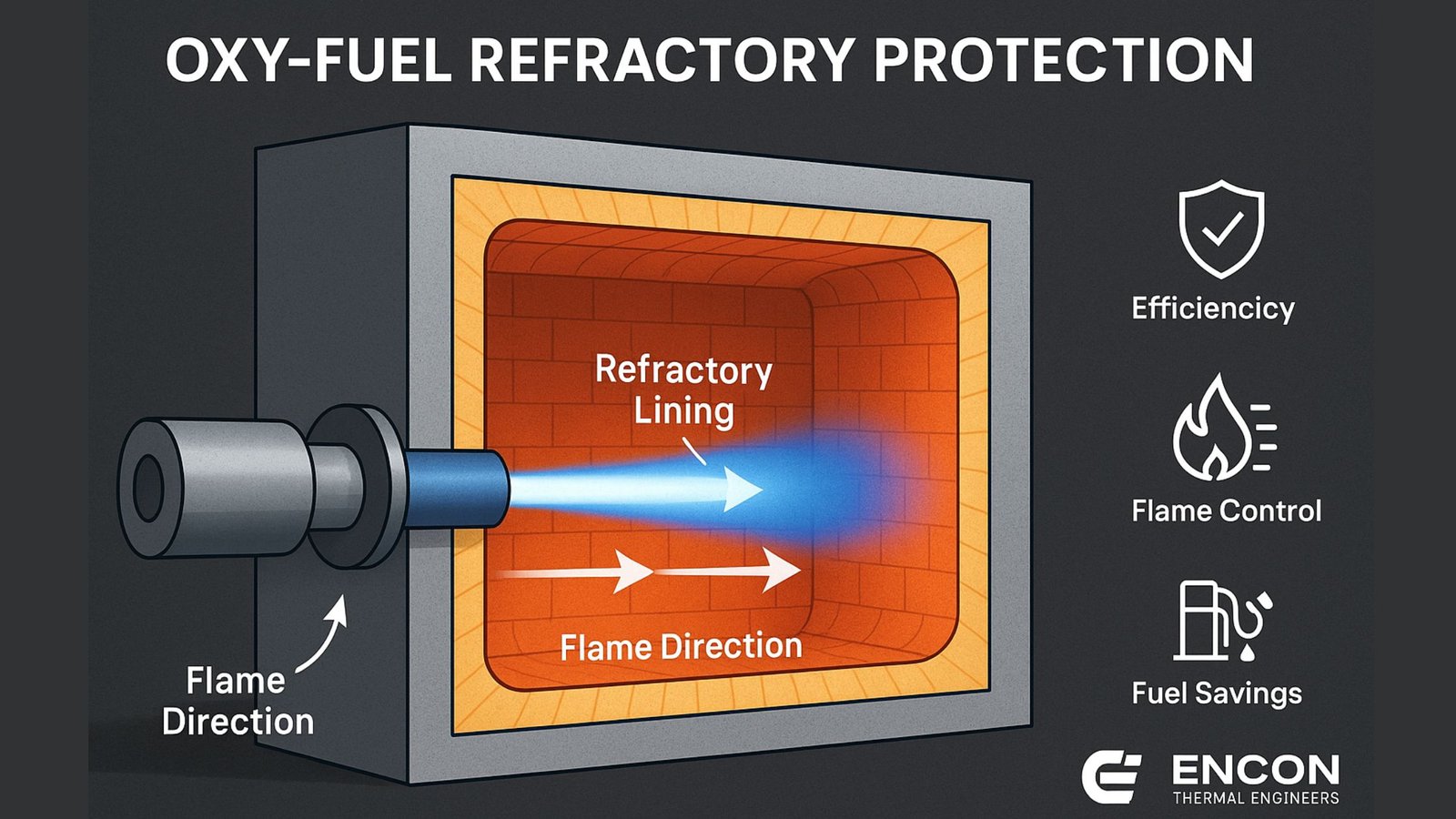

Oxy-Fuel Refractory Protection refers to the design and operation strategies of oxy-fuel burners that reduce direct damage to furnace linings.

Unlike conventional air-fuel burners, oxy-fuel systems:

- Burn cleaner

- Operate at higher efficiency

- Generate less flue gas

- Allow for better control of flame characteristics

These properties enable better protection of the furnace refractory through controlled heat input and flame shaping.

🔥 How Oxy-Fuel Burners Help Reduce Refractory Damage

🔹 Flame Shaping & Direction Control

Modern oxy-fuel burners are engineered to direct flame away from the refractory walls. By adjusting flame length and velocity, impingement is minimized—extending refractory life.

🔹 Less Slag & Ash Formation

Because oxy-fuel combustion is cleaner and more complete, there’s a significant reduction in unburnt carbon and ash. This limits corrosive deposits on refractory surfaces.

🔹 Reduced Thermal Shock

Efficient heat distribution and stable flame temperature mean fewer thermal fluctuations, which prevents cracking and spalling of refractory material.

🔹 Optimized Oxygen-to-Fuel Ratios

By controlling oxygen flow precisely, the risk of localized overheating or oxidizing attacks on refractory is minimized.

These features make Oxy-Fuel Refractory Protection highly effective in furnaces that demand longevity and reliability, especially in steel and non-ferrous metal melting.

🏭 Where It Matters Most: Industrial Applications

Oxy-fuel refractory protection is a must in industries that experience:

Industry | Application | Risk |

Steel | Reheating & forging furnaces | Slag buildup, flame impingement |

Glass | Melting tanks | High thermal load, alkali attack |

Aluminum | Holding & melting furnaces | Oxidation & hot spots |

Ceramics | Kilns | Refractory cracking, uneven heating |

Foundries | Cupola & crucible furnaces | Abrasive wear, carbon attack |

With Encon’s custom burner designs and advanced control systems, these risks are mitigated without compromising productivity.

🛠️ Our Oxy-Fuel Burner Technology

At Encon Thermal Engineers, we’ve developed state-of-the-art low NOx oxy-fuel burners with integrated flame-control mechanisms specifically for Oxy-Fuel Refractory Protection.

Key Features:

- Flame direction control

- Adjustable flame length

- Optimized mixing for complete combustion

- Suitable for both retrofits and new furnaces

- Custom designs for round, rectangular, or tunnel kilns

We also offer CFD analysis and simulation to ensure that flame profiles align with refractory protection goals.

Also Read – Oxy-Fuel Combustion Emission Control for NOx and SOx Reduction

📈 Cost Savings Through Refractory Protection

Benefit | Impact |

🔧 Reduced Repair Frequency | Longer refractory service life |

🕒 Lower Downtime | Better production uptime |

🔋 Energy Savings | Efficient heat containment |

💰 Reduced Maintenance Costs | Fewer relining and patchwork expenses |

🔥 Higher Thermal Efficiency | Better heat retention and productivity |

🧠 Expert Tip: When to Upgrade to Oxy-Fuel

You should consider oxy-fuel retrofitting if:

- Your furnace needs frequent refractory relining

- You operate at high temperatures regularly

- You see signs of uneven wear or flame impingement

- You want to reduce fuel usage and emissions simultaneously

🏆 Why Encon?

- ✅ 40+ years of industrial furnace expertise

- ✅ Custom burner design based on your furnace architecture

- ✅ PAN-India installation & after-sales support

- ✅ Proven success in refractory life extension

Our commitment is to deliver intelligent combustion that not only saves fuel but also saves your infrastructure.

📢 Final Thoughts: Protect Heat, Preserve Life

Refractory protection is not just a cost-saving measure—it’s a performance and safety priority. With Oxy-Fuel Refractory Protection, industries can achieve longer operational runs, safer environments, and reduced maintenance burden.

📞 Call to Action

Upgrade your furnace with Oxy-Fuel Refractory Protection today.

📲 Contact Encon Thermal Engineers for a custom solution that safeguards your refractory and boosts your efficiency.