How Oxy-Fuel Burners Improve Industrial Heating Efficiency

The industrial heating sector has undergone a remarkable transformation with the advent of oxy-fuel burners. These innovative systems have redefined heating methodologies, offering exceptional efficiency and environmental advantages. How Oxy-Fuel Burners Revolutionize Industrial Heating is evident in the way they improve energy utilization and reduce emissions. As the industrial sector increasingly prioritizes sustainable and cost-effective combustion solutions, oxy-fuel burners have become a cornerstone technology. This piece examines how oxy-fuel burners improve industrial heating and their rising significance across manufacturing sectors.

What are Oxy-Fuel Burners?

Oxy-fuel burners are advanced combustion units that utilize pure oxygen instead of air for combustion. Unlike standard burners relying on atmospheric air (with only 21% oxygen), these Systems use a highly concentrated oxygen stream, often surpassing 90% purity. This method ensures a more efficient and cleaner combustion process. An oxy-fuel burner’s primary components – fuel and oxygen inlets, mixing chamber, and combustion nozzle – work in harmony to create a precisely managed, high-intensity flame that maximizes heat transfer while minimizing waste.

Benefits of Oxy-Fuel Burners

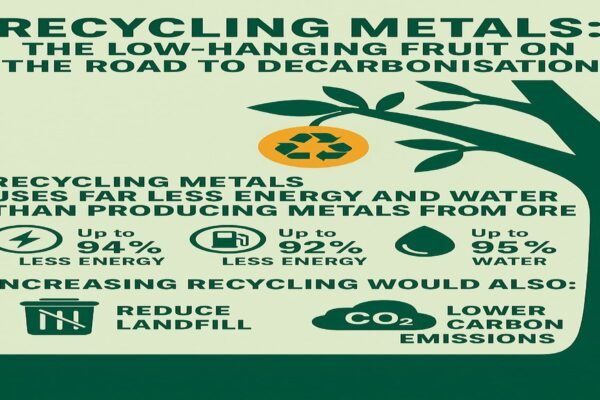

- Enhanced Energy Efficiency: Oxy-fuel burners excel in energy efficiency, a primary benefit of their design. By eliminating the need to heat atmospheric nitrogen, these systems achieve higher flame temperatures and more precise heat transfer. This allows industrial processes to reach target temperatures faster and with less fuel consumption, resulting in significant energy savings and productivity gains across various industrial applications.

- Improved Combustion Quality: The combustion quality of oxy-fuel burners far surpasses traditional air-fuel systems. By removing nitrogen from the combustion process, these burners dramatically reduce nitrogen oxide (NOx) emissions, a major contributor to air pollution. The more complete combustion also leads to lower carbon monoxide (CO) emissions. This improved combustion quality not only benefits the environment but also helps industries meet stringent emission regulations.

- Cost Savings: While the initial investment in oxy-fuel technology may be higher, the long-term economic benefits are considerable. Improved fuel efficiency translates to lower fuel consumption for the same heating output, reducing ongoing fuel costs. Moreover, the reduced maintenance needs and longer equipment lifespan associated with oxy-fuel burners contribute to overall operational savings. These financial benefits make oxy-fuel burners an attractive option for industries looking to optimize their heating processes and improve their bottom line.

Applications of Oxy-Fuel Burners in Industry

Oxy-fuel burners have found widespread use across various industries, transforming heating processes in multiple sectors:

Steel Manufacturing

In steelmaking, oxy-fuel combustion significantly improves furnace efficiency. The technology enables quicker melting times, reduced energy consumption, and better temperature control, contributing to higher-quality steel production and lower environmental impact.

Glass Production

The glass industry has widely adopted oxy-fuel technology, especially in melting furnaces. The higher flame temperatures and improved heat transfer characteristics result in more efficient glass melting, fewer bubbles, and enhanced glass quality. This technology allows glass producers to increase output while reducing energy use and emissions.

Waste Incineration

Oxy-fuel burners have proven highly effective in waste incineration processes. The technology allows for more complete combustion of waste materials, reducing residual ash volume and minimizing harmful emissions. This application not only improves waste disposal efficiency but also contributes to environmental conservation.

Other Applications

Beyond these core applications, oxy-fuel burners are gaining traction in industries such as ceramics production, non-ferrous metal processing, and chemical manufacturing. The versatility and efficiency of oxy-fuel technology make it an attractive heating solution for a wide range of industrial applications.

ENCON Thermal Engineers' Oxy-Fuel Solutions

Our Expertise

At ENCON Thermal Engineers, we specialize in cutting-edge industrial heating solutions, with a focus on oxy-fuel technology. Our team of expert engineers and technicians is dedicated to developing customized oxy-fuel burner systems that meet the specific needs of our clients across various industries.

Product Offerings

We offer a comprehensive range of oxy-fuel burner products, from compact units for small-scale operations to large, high-capacity systems for major industrial facilities. Our solutions are designed to maximize efficiency, reduce emissions, and provide long-term cost savings for our clients.

How to Implement Oxy-Fuel Burners in Your Facility

- Assessment: Integrating oxy-fuel burners into your industrial facility begins with a thorough evaluation of your current heating processes and requirements. ENCON Thermal Engineers conducts comprehensive site surveys and process analyses to determine the most suitable oxy-fuel solution for your specific needs. Once the optimal system is identified, we guide you through the installation process, ensuring minimal disruption to your operations.

- Installation Process: The installation of oxy-fuel burners typically involves retrofitting existing furnaces or integrating new oxy-fuel systems into your production line. Our skilled technicians handle all aspects of the installation, from equipment setup to control system integration. Following installation, we provide comprehensive training to your staff to ensure proper operation and maintenance of the new system.

- Maintenance and Support: ENCON Thermal Engineers is committed to providing continuous support and maintenance services to keep your oxy-fuel burners operating at peak efficiency. Our maintenance programs include regular inspections, performance optimizations, and prompt repairs when needed. This comprehensive support ensures that you continue to reap the benefits of your oxy-fuel system for years to come.

Conclusion

Oxy-fuel burners have undeniably transformed industrial heating processes, offering a powerful combination of increased efficiency, reduced emissions, and long-term cost savings. As industries continue to seek more sustainable and economical combustion solutions, the adoption of oxy-fuel technology is set to grow. ENCON Thermal Engineers stands at the forefront of this revolution, providing state-of-the-art oxy-fuel burner systems tailored to meet the diverse needs of modern industry. If you’re looking to optimize your heating processes, reduce your environmental footprint, and drive down operational costs, we invite you to contact ENCON Thermal Engineers. Our team of experts is ready to help you harness the power of oxy-fuel technology and transform your industrial heating operations.