Introduction

In industrial combustion, waste heat refers to thermal energy carried away by exhaust gases after fuel combustion. Without recovery mechanisms, this energy is lost despite being fully usable.

In many applications, this heat transfer is achieved using recuperative heat recovery systems that preheat combustion air using hot exhaust gases before they are discharged.

For high-temperature and continuous-duty applications, industries often evaluate regenerative burner technology, where thermal energy is alternately stored and reused to maximize efficiency.

By integrating waste heat recovery in burners, industries can reduce fuel consumption while improving flame stability. Preheated air promotes more complete combustion, minimizes temperature fluctuations, and enhances control over temperature-sensitive processes.

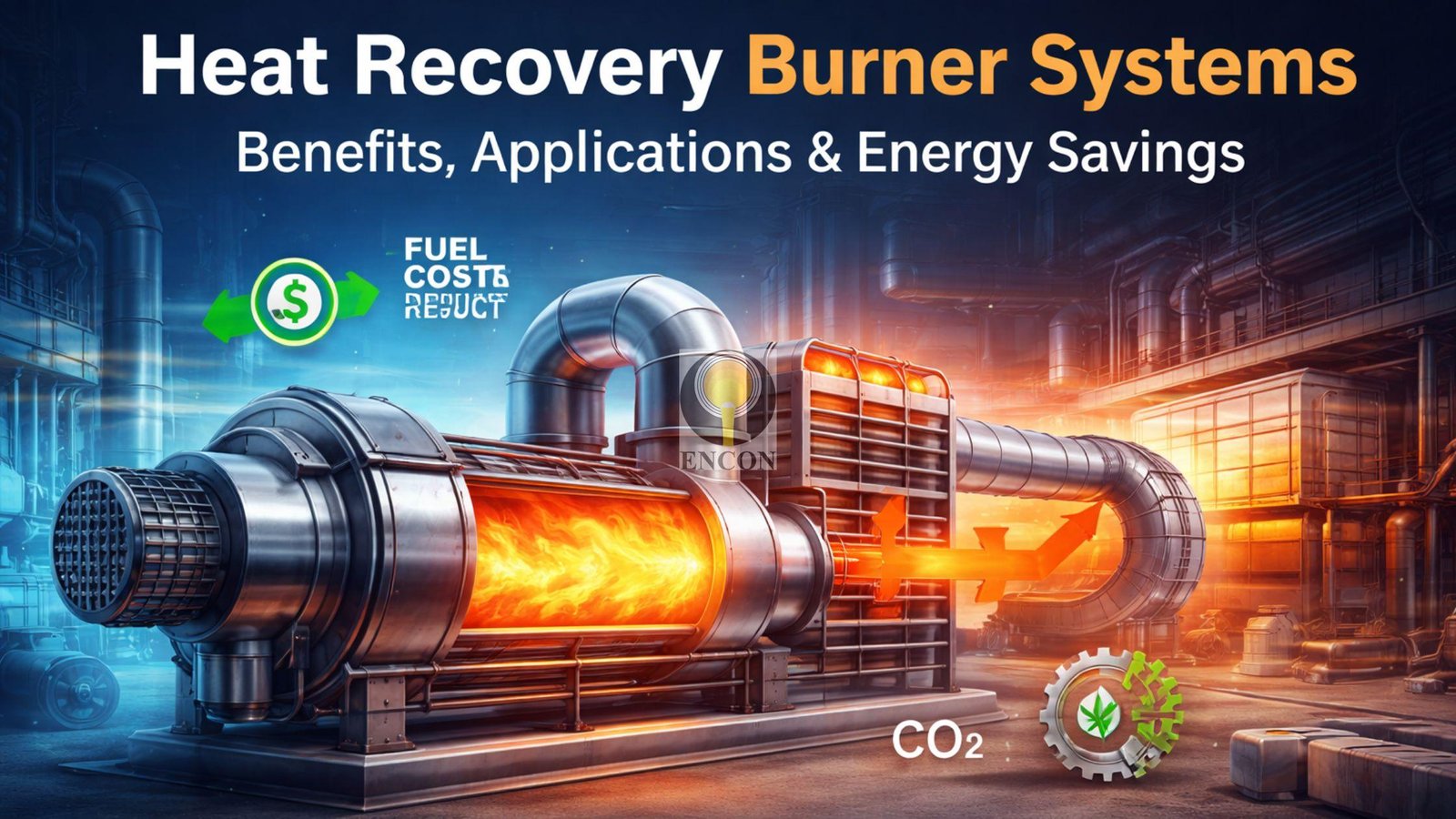

What Are Heat Recovery Burner Systems?

Heat recovery burner systems are advanced combustion arrangements designed to utilize the thermal energy present in exhaust gases. Instead of allowing flue gases to exit at high temperatures, these systems channel the heat through specially designed components before discharge.

The core working principle involves transferring exhaust heat to incoming combustion air. As the air enters the burner at a higher temperature, less fuel is required to achieve the desired flame intensity and process temperature. Compared to conventional burners, heat recovery–enabled burners significantly reduce thermal losses while maintaining stable combustion.

A key distinction lies in combustion air preheating. Traditional burners rely on ambient air, whereas heat recovery designs use preheated air, resulting in higher flame temperatures, improved efficiency, and better overall thermal control.

How Waste Heat Recovery in Burners Improves Efficiency

In industrial combustion, waste heat refers to thermal energy carried away by exhaust gases after fuel combustion. Without recovery mechanisms, this energy is lost despite being fully usable.

In many applications, this heat transfer is achieved using recuperative heat recovery systems that preheat combustion air using hot exhaust gases before they are discharged.

For high-temperature and continuous-duty applications, industries often evaluate regenerative burner technology, where thermal energy is alternately stored and reused to maximize efficiency.

By integrating waste heat recovery in burners, industries can reduce fuel consumption while improving flame stability. Preheated air promotes more complete combustion, minimizes temperature fluctuations, and enhances control over temperature-sensitive processes.

Key Benefits of Heat Recovery Burner Systems

🔹 Significant Fuel and Energy Savings

When designed and applied correctly, Heat Recovery Burner Systems can deliver fuel savings typically ranging from 10% to 30%, depending on process temperature and duty cycle. These reductions are achieved without altering production capacity or compromising safety. Over time, lower fuel consumption directly impacts operating costs, making such systems particularly valuable for plants with continuous or high-temperature operations.

🔹 Lower Emissions and Sustainable Operation

Improved combustion efficiency leads to reduced CO₂ output per unit of production. Additionally, controlled flame characteristics help limit NOx formation, supporting compliance with environmental regulations and internal sustainability targets.

🔹 Improved Thermal Efficiency and Process Stability

Preheated combustion air allows furnaces and ovens to reach operating temperatures faster. More importantly, consistent heat input ensures uniform product quality, reduced rejects, and smoother process control.

Industrial Heat Recovery Solutions for Modern Manufacturing

Energy-intensive industries are increasingly adopting industrial heat recovery solutions to remain competitive in markets where margins are under constant pressure. These systems are no longer limited to new installations; many can be integrated into existing furnaces and ovens with minimal structural modification.

Sectors such as steel, aluminum, glass, ceramics, and chemical processing benefit significantly due to their high exhaust temperatures and continuous operations. Proper integration ensures compatibility with existing control systems while delivering tangible efficiency improvements without production downtime.

Applications of Heat Recovery Burner Systems

🔹 Heat Recovery for Industrial Furnaces

Reheating furnaces, walking beam furnaces, and both batch and continuous furnaces can benefit from optimized burner configurations. The application of heat recovery for industrial furnaces allows operators to maintain precise thermal profiles while reducing overall fuel demand.

🔹 Industrial Ovens and Process Heating Equipment

Drying ovens, curing systems, and coating lines often operate for extended hours at moderate to high temperatures. Heat recovery integration in these systems improves energy utilization and ensures consistent results across production cycles.

Role of Waste Heat Recovery in Burners for Cost Reduction

From a financial perspective, investments in energy optimization are increasingly evaluated through return-on-investment metrics. By applying waste heat recovery in burners, plant owners can significantly reduce dependence on primary fuel sources.

Lower fuel usage not only cuts monthly operating expenses but also insulates businesses from fuel price volatility. Additionally, improved operational efficiency often leads to reduced maintenance frequency, as stable combustion places less thermal stress on equipment.

Choosing the Right Industrial Heat Recovery Solution

Selecting the correct system requires careful evaluation rather than adopting standardized designs. Industrial heat recovery solutions must be matched to specific process requirements, including furnace type, fuel used, and operating temperature range.

Customization is critical. Factors such as space constraints, exhaust composition, and load variability influence system performance. Avoiding one-size-fits-all configurations ensures that recovery systems deliver expected efficiency gains without introducing operational complexity.

Why Heat Recovery Burner Systems Are a Smart Investment

Beyond immediate fuel savings, these systems offer long-term financial advantages through reduced energy costs and improved process reliability. Sustainability benefits, including lower emissions and easier regulatory compliance, further strengthen their value proposition.

For energy-intensive industries, these systems provide a competitive edge by reducing production costs while maintaining consistent output quality. Organizations planning such upgrades can benefit from consulting Encon’s engineering team to evaluate application-specific feasibility and performance outcomes.

Conclusion

Heat recovery–enabled combustion systems represent a practical approach to addressing rising energy costs and efficiency demands in industrial operations. By reclaiming exhaust heat, industries can achieve meaningful fuel savings, improved thermal stability, and reduced environmental impact. From furnaces and ovens to diverse process heating applications, the benefits extend across multiple manufacturing sectors.

As energy efficiency becomes central to industrial strategy, exploring customized solutions tailored to specific operating conditions is essential. With deep technical expertise and process understanding, experienced engineering partners help industries transition toward smarter, more efficient combustion systems—delivering lasting value without disruption.