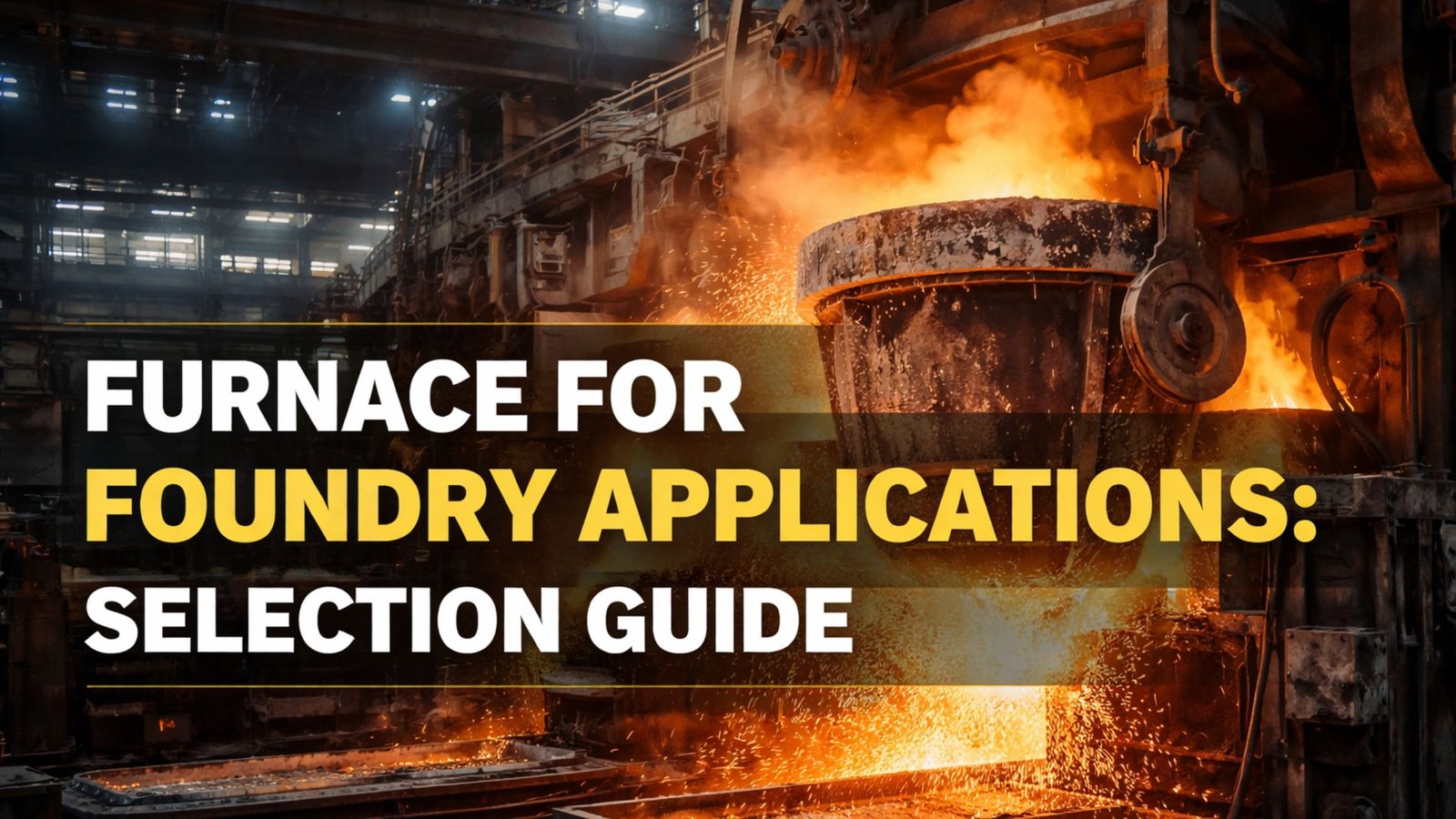

Introduction In foundry operations, furnace selection is not merely an equipment decision—it directly influences productivity, metal quality, fuel consumption, and overall operating costs. A furnace that is poorly matched to process requirements can lead to inconsistent melting, excessive oxidation, higher fuel bills, and frequent downtime. Many foundries face challenges because furnaces are often chosen based […]

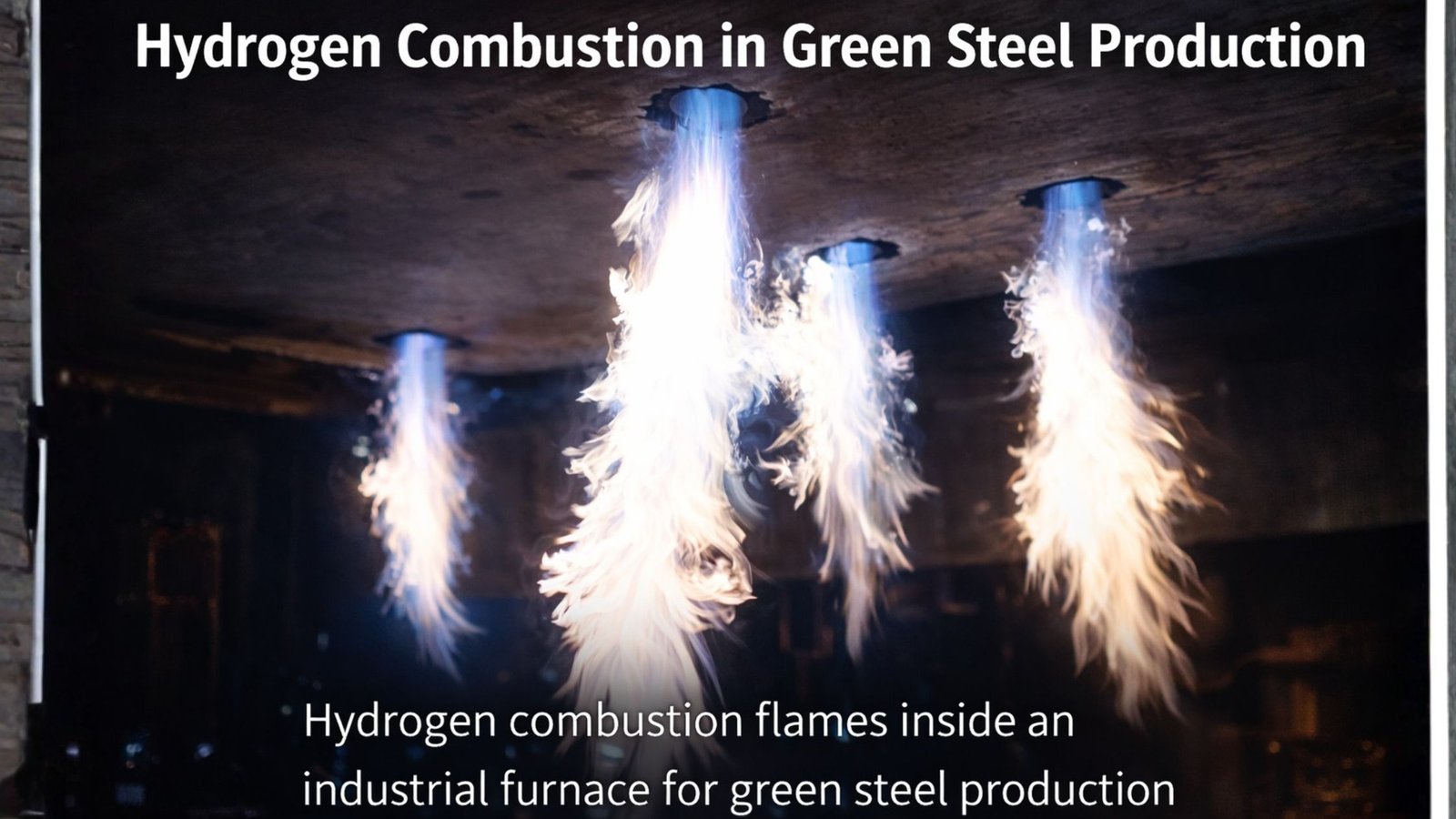

Introduction The global steel industry is undergoing one of the most important transitions in its history. With rising pressure to reduce emissions and align with international climate commitments, manufacturers are now seeking cleaner alternatives to traditional carbon-based steelmaking. Among the most promising breakthroughs is Green Steel Production with Hydrogen Combustion, a method that replaces fossil […]

Introduction Industrial furnaces are the heart of manufacturing units in industries such as steel, cement, glass, petrochemicals, and many others. However, with rising energy costs and increasingly stringent environmental standards, older furnaces often struggle to meet modern efficiency and sustainability standards. This is where Industrial Furnace Retrofitting emerges as a smart, cost-effective alternative to complete […]

In today’s energy-intensive industrial landscape, furnace efficiency isn’t just about saving fuel—it’s about survival. Rising fuel costs, stricter environmental regulations, and growing sustainability commitments mean industries must adopt smarter, cleaner technologies to remain competitive. Among the most effective solutions available are regenerative burners for furnaces—advanced combustion systems that recover and reuse heat from flue gases. […]

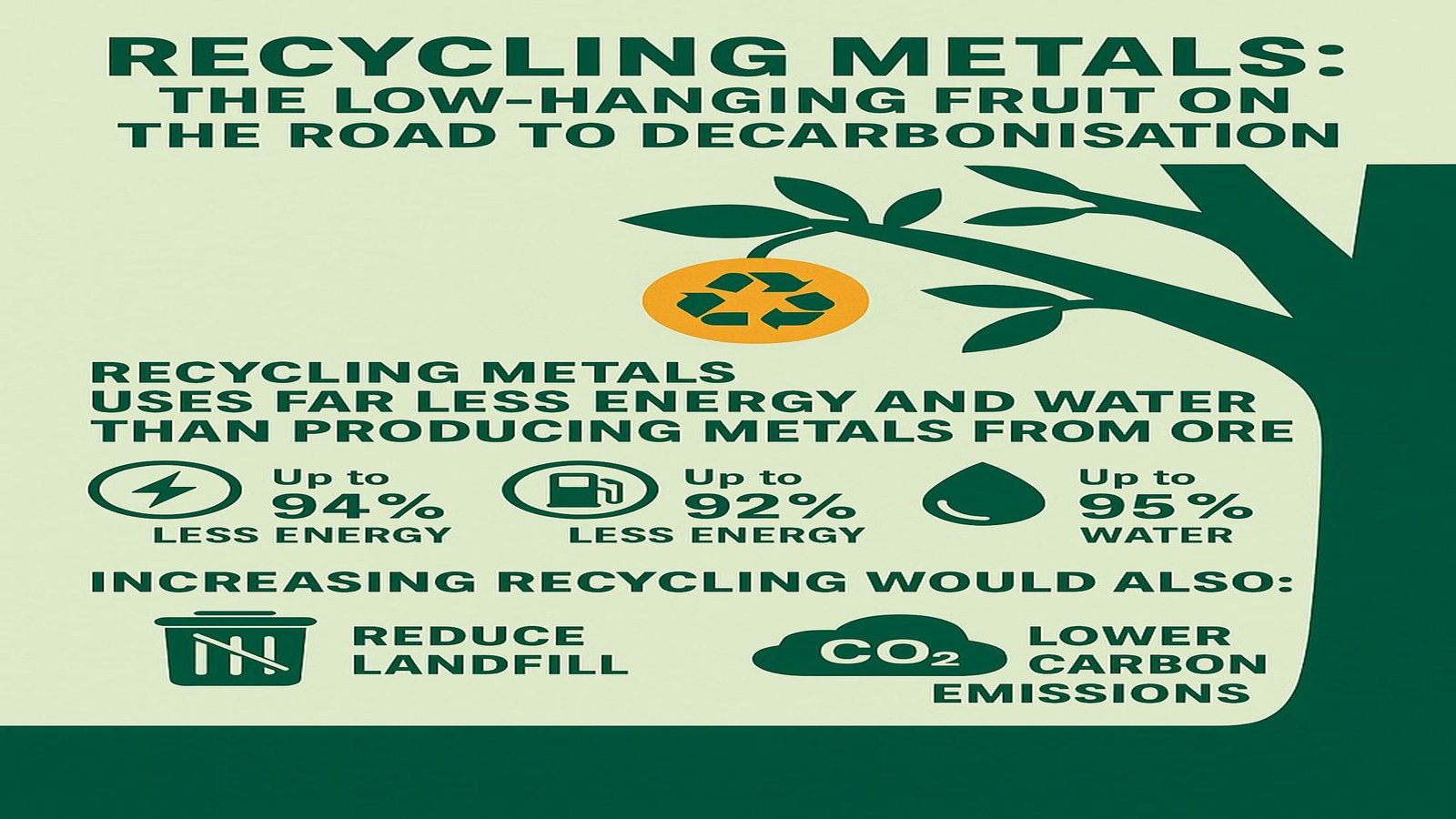

When conversations around decarbonisation, hydrogen, and clean technologies dominate the sustainability agenda, one powerful solution often remains underappreciated: recycling and decarbonisation. Recycling is not just about reusing materials; it is one of the most effective tools available to cut emissions, save water, reduce waste, and protect natural ecosystems. Yet despite overwhelming evidence, the industrial sector […]

India’s steel industry stands at the center of the nation’s decarbonisation challenge — and its opportunity. With the Government announcing a ₹5,000 crore National Mission for Sustainable Steel, the message is clear: the sector must become cleaner, greener, and globally competitive. This initiative is not just a policy announcement; it is a signal for transformation. […]

Introduction Cement production is one of the most energy-intensive industrial processes in the world. Heating the rotary kilns used for clinker production consumes significant amounts of fuel, traditionally relying on coal. However, with rising energy costs, stricter emission norms, and the urgent need to cut carbon footprints, alternative technologies are gaining traction. One of the […]

Introduction Industrial heating processes such as kilns and boilers are at the heart of manufacturing sectors like cement, steel, glass, ceramics, and power generation. However, these processes are also major contributors to greenhouse gas emissions, particularly CO₂ and NOx. As industries face growing environmental regulations, rising fuel costs, and sustainability pressures, the search for cleaner […]

Driving Industrial Transformation: ENCON’s ESCO Model for Energy Efficiency In the face of rising fuel prices, environmental mandates, and increasing competition, industrial enterprises are under pressure to reduce energy costs and emissions—without compromising productivity. Enter the ESCO model, a revolutionary approach where energy efficiency becomes not just an operational goal, but a guaranteed outcome. At […]

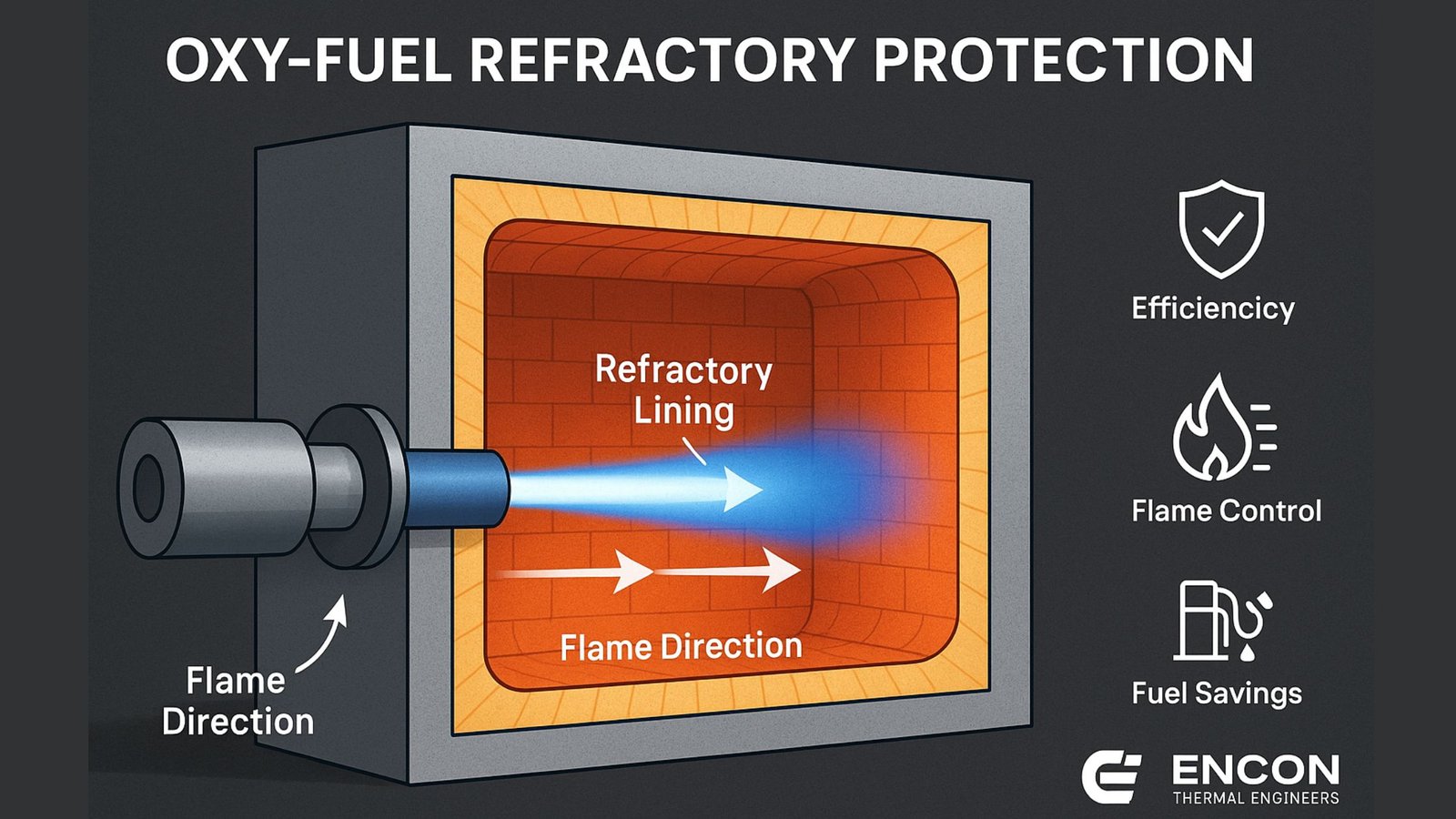

🔥 Introduction: The Hidden Cost of Furnace Operation Industrial furnaces are the workhorses of sectors like steel, glass, ceramics, aluminum, and petrochemicals. However, one of the major challenges in furnace operation is refractory wear—a silent yet significant factor affecting operational costs, energy efficiency, and production downtime. The integration of Oxy-Fuel Refractory Protection has emerged as […]