Introduction

In foundry operations, furnace selection is not merely an equipment decision—it directly influences productivity, metal quality, fuel consumption, and overall operating costs. A furnace that is poorly matched to process requirements can lead to inconsistent melting, excessive oxidation, higher fuel bills, and frequent downtime. Many foundries face challenges because furnaces are often chosen based on generic specifications or initial cost rather than actual application needs.

Selecting the right furnace for foundry applications requires a deeper understanding of metal characteristics, production volume, and workflow integration. Each foundry operates under unique constraints related to fuel availability, batch size, and quality expectations. When these factors are carefully evaluated, the furnace becomes a performance enabler rather than a bottleneck. This guide explains how foundries can make informed decisions by aligning furnace design and capability with real-world operating demands.

Understanding Furnace Requirements in Foundry Operations

Furnaces play a central role in foundry processes, including metal melting, holding molten metal at controlled temperatures, and reheating for casting or secondary operations. The performance expectations from a furnace vary significantly depending on several factors.

Metal type is a primary consideration. Ferrous metals require higher temperatures and robust refractory systems, while aluminum and other non-ferrous metals demand precise temperature control to avoid oxidation and metal loss. Production volume also affects furnace selection, as high-output foundries need systems designed for continuous or semi-continuous operation.

Fuel availability—whether gas, oil, or electricity—further shapes furnace configuration. Aligning furnace design with the foundry workflow ensures smooth material movement, predictable cycle times, and stable production planning. Many foundries evaluate industrial furnace solutions for foundries through experienced manufacturers like Encon Thermal Engineers, who design systems based on real production conditions rather than standard catalog specifications.

Types of Foundry Furnace Systems

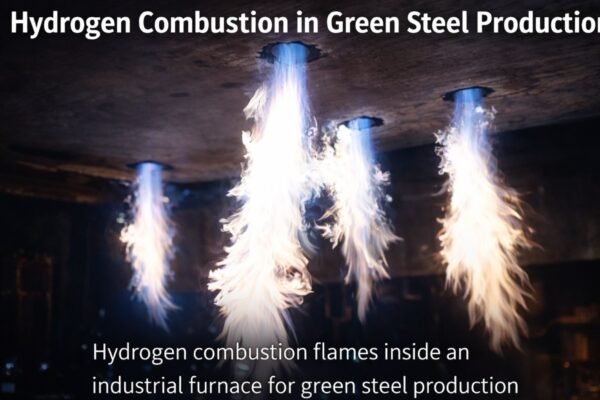

Foundries employ different foundry furnace systems based on operational scale, fuel economics, and metal type. Common systems include gas-fired, oil-fired, and electric furnaces.

Gas-fired furnaces are widely used due to relatively clean combustion and good temperature control. Oil-fired systems are often preferred in regions with limited gas infrastructure, offering flexibility but requiring careful emission management. Electric furnaces provide precise control and low on-site emissions, though operating costs depend heavily on power tariffs.

Each system has advantages and limitations. The right choice depends on balancing energy efficiency, operating cost, environmental compliance, and maintenance requirements within the foundry environment.

Industrial Furnaces for Foundries and Their Applications

Unlike general-purpose heating equipment, industrial furnaces for foundries are engineered to withstand extreme thermal loads, repetitive cycles, and demanding metallurgical conditions. These furnaces are designed to deliver uniform temperature distribution, which is critical for consistent metal quality.

For cast iron applications, furnaces must handle high melting temperatures and continuous operation. Aluminum processing requires gentler heating with tight control to prevent dross formation. Non-ferrous metals often need specialized linings and burner configurations to maintain purity, particularly in dedicated systems for aluminum melting applications, where metal yield directly impacts profitability.

The reliability of industrial furnaces for foundries lies in their ability to provide stable thermal conditions while integrating seamlessly with casting lines and material handling systems.

Selecting the Right Metal Melting Furnace for Foundry Operations

A reliable metal melting furnace for foundry use is defined by its ability to melt metal efficiently while preserving metallurgical properties. Key performance parameters include melting rate, achievable temperature range, and consistency across batches.

Fuel efficiency is another critical factor. Efficient furnaces reduce specific fuel consumption per ton of metal melted, directly impacting operating margins. Additionally, furnace design should minimize oxidation and metal loss, especially in aluminum and copper-based alloys, where yield losses can be significant.

Selecting the right metal melting furnace for foundry operations involves evaluating both technical capability and long-term operating behavior under real production conditions.

Key Factors to Consider When Choosing a Furnace for Foundry Applications

🔹 Type of Metal Being Processed

The furnace for foundry applications must be compatible with the specific metal being processed. Aluminum, ferrous, and non-ferrous metals each impose different thermal and material challenges.

🔹 Production Capacity and Batch Size

Foundries operating continuous lines require furnaces built for sustained output, while batch operations may prioritize flexibility and quick changeovers.

🔹 Fuel Type and Energy Efficiency

Fuel choice affects not only operating cost but also emissions, safety, and maintenance. Many modern foundries improve performance by improving thermal efficiency through pre-heating systems, which recover waste heat and reduce overall fuel consumption.

🔹 Maintenance and Operating Costs

Long-term costs often outweigh initial investment. Ease of maintenance, refractory life, and spare availability should factor into decision-making.

Energy Efficiency and Performance Expectations in Foundry Furnaces

Modern foundries increasingly prioritize energy efficiency as a strategic objective. High-quality insulation, optimized combustion systems, and efficient heat transfer reduce energy losses significantly.

Furnace design directly influences fuel consumption. Poor airflow, uneven heating, or outdated controls can increase operating costs. Efficient furnaces support predictable energy usage, helping foundries manage costs and meet sustainability targets in competitive markets.

Role of Industrial Furnaces for Foundries in Process Optimization

Well-designed industrial furnaces for foundries contribute to faster cycle times and consistent output. Stable temperature control ensures uniform metal properties, reducing casting defects and rework.

Improved reliability also minimizes unplanned downtime. When furnaces operate consistently within design parameters, maintenance becomes predictable, allowing better production planning and resource utilization.

Common Mistakes to Avoid When Selecting Foundry Furnace Systems

One frequent mistake is choosing equipment based solely on upfront cost, ignoring lifecycle expenses. Another is failing to account for future capacity expansion, leading to premature upgrades.

Overlooking service support and technical assistance can also create long-term challenges. Foundry furnace systems must be supported by expertise that understands process behavior, not just equipment specifications.

Why the Right Furnace for Foundry Applications Is a Long-Term Investment

Selecting the correct furnace for foundry applications ensures operational reliability and consistent production quality. Over time, energy savings, reduced metal losses, and lower maintenance requirements contribute to measurable financial benefits.

A well-matched furnace supports stable workflows and enables foundries to respond to changing production demands without compromising efficiency. In competitive markets, such investments strengthen both operational resilience and profitability.

Conclusion

Choosing the right furnace is a strategic decision that shapes foundry performance for years to come. Every foundry has unique requirements influenced by metal type, production scale, and energy considerations. Evaluating furnaces based on application fit, efficiency, and lifecycle value ensures sustainable operations and consistent quality.

By focusing on process-specific needs rather than generic specifications, foundries can unlock higher productivity and lower operating costs. Foundries looking to upgrade or install new systems are encouraged to discuss their foundry furnace requirements with technical specialists who understand real-world operating conditions.