Introduction

The global steel industry is undergoing one of the most important transitions in its history. With rising pressure to reduce emissions and align with international climate commitments, manufacturers are now seeking cleaner alternatives to traditional carbon-based steelmaking. Among the most promising breakthroughs is Green Steel Production with Hydrogen Combustion, a method that replaces fossil fuels with hydrogen to achieve near-zero carbon output.

Hydrogen offers a powerful pathway for heavy industries to contribute to worldwide decarbonization targets, especially as renewable energy becomes more accessible. As governments and industries invest heavily in sustainable metallurgy, the spotlight is shifting toward advanced thermal technologies that support the Future of Green Steel Production with Hydrogen Combustion.

This blog explores how hydrogen combustion is reshaping steelmaking, the technologies required, and why it represents a major milestone in industrial sustainability.

Understanding the Concept of Green Steel

“Green steel” refers to steel produced with minimal carbon emissions throughout the manufacturing process. Traditional steelmaking relies heavily on coal, coke, and natural gas—fuels that contribute significantly to global CO₂ output. As environmental regulations tighten, industries are turning toward cleaner thermal and metallurgical methods.

One of the most transformative solutions is Hydrogen-Based Steelmaking, which replaces carbon-rich fuels with hydrogen. When hydrogen is burned or used as a reducing agent, the primary byproduct is water vapor, not carbon dioxide. This creates an opportunity for Low-Carbon Steel Manufacturing at scale, enabling steel plants to meet sustainability targets without compromising productivity or quality.

With hydrogen emerging as a key energy vector in global decarbonization plans, green steel has become central to the future of metallurgy.

The Role of Hydrogen Combustion in Steelmaking

In steel plants, fuel is required for processes such as reheating, melting, and heat treatment. Traditionally, these operations depend on carbon-intensive fuels that emit large quantities of CO₂.

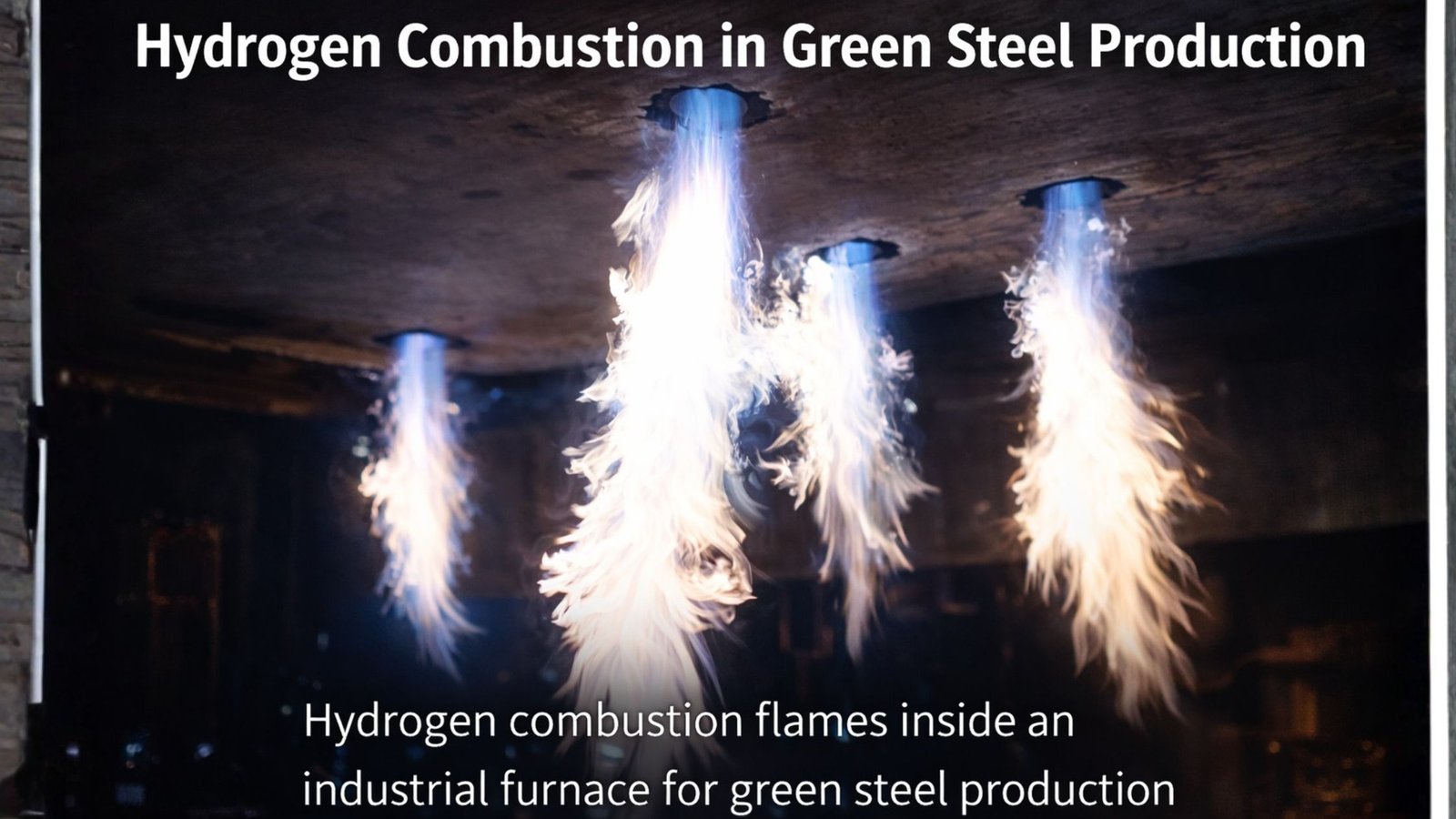

Green Steel Production with Hydrogen Combustion offers a cleaner alternative by using hydrogen as the primary energy source. Advanced industrial systems, such as hydrogen combustion technologies, are now enabling steel manufacturers to replace fossil fuels while maintaining high thermal efficiency.

Hydrogen combustion produces exceptionally high flame temperatures and emits zero carbon dioxide, making it an ideal replacement for fossil fuels. It also reduces pollutants such as SOx and particulate matter, leading to cleaner furnace atmospheres and improved operational stability.

Hydrogen integrates efficiently with advanced burner technologies, recuperators, and furnace designs that focus on thermal uniformity, heat recovery, and energy optimization. Modern systems are capable of adapting combustion parameters to hydrogen’s unique flame characteristics, ensuring safe and efficient performance without compromising process quality.

As steelmaking moves toward decarbonization, hydrogen combustion stands out as a technologically viable and environmentally sound solution.

Technological Requirements for Hydrogen-Based Steelmaking

Transitioning to Hydrogen-Based Steelmaking requires upgrades across critical areas of thermal equipment. Furnaces must be designed or retrofitted to handle hydrogen’s rapid flame speed and higher combustion intensity. Burners need specialized nozzles, control valves, and flame stabilization systems that prevent flashback while maintaining uniform heating profiles.

Heat recovery units, such as regenerators and recuperators, must be optimized to work effectively with hydrogen’s combustion properties, ensuring maximum energy efficiency. Materials used inside the furnace—including refractories and metallic components—must withstand elevated temperatures and thermal cycling caused by hydrogen’s unique flame behavior.

These requirements align with the broader goal of Low-Carbon Steel Manufacturing, where efficient heat transfer, reduced heat loss, and improved combustion stability are essential. Advanced industrial solutions today incorporate hydrogen-ready burners, intelligent automation systems, and high-efficiency heat recovery modules to create a robust foundation for future green steel plants.

Challenges in Adopting Hydrogen Combustion for Steel Production

While the promise of Green Steel Production with Hydrogen Combustion is strong, several challenges must be addressed before large-scale adoption. The cost of hydrogen remains one of the most significant barriers, especially for green hydrogen produced using renewable energy. Infrastructure for storage, distribution, and safety systems is still developing, which impacts the feasibility for many regions.

Hydrogen’s low energy density and high diffusivity require advanced safety protocols, especially in high-temperature industrial environments. Retrofitting existing furnaces and burners also poses technical challenges, requiring specialized engineering and precise combustion control.

However, rapid advancements in technology and supportive government policies are gradually closing these gaps. ESCO-based energy efficiency models, renewable-linked hydrogen production, and next-generation combustion designs are making hydrogen integration more achievable. Industries preparing for this transformation can benefit significantly from early adoption strategies that combine safety, efficiency, and long-term sustainability.

Future Outlook: The Path Toward Decarbonized Steel

Worldwide momentum is building around hydrogen as a clean energy vector, with major steel-producing nations investing in pilot plants, R&D programs, and hydrogen corridors. Government incentives, carbon pricing mechanisms, and renewable energy integration are accelerating the shift toward Low-Carbon Steel Manufacturing.

India, too, has committed to net-zero goals, with the steel sector identified as a key area for transformation. The adoption of hydrogen aligns perfectly with national and global sustainability targets, positioning industries for long-term competitiveness.

As hydrogen availability grows and technology matures, Green Steel Production with Hydrogen Combustion is set to become the defining standard for sustainable metallurgy, reshaping the entire supply chain from raw materials to finished products.

Conclusion

Hydrogen-powered steelmaking is redefining how heavy industries operate, offering a cleaner, smarter, and future-ready approach to metal production. Green Steel Production with Hydrogen Combustion represents the most powerful step toward industrial decarbonization, enabling manufacturers to reduce emissions while improving thermal efficiency.

To explore advanced hydrogen-ready combustion systems for your steel plant, contact Encon Thermal Engineers and begin your transition toward sustainable, low-carbon steel production.