Introduction – The Need for Efficient Combustion in Oil and Gas

The oil and gas industry plays a pivotal role in powering global economies. Yet, it faces mounting challenges: rising fuel costs, stringent emission regulations, and ambitious sustainability goals. Combustion efficiency has become a central focus for operators looking to optimize processes while minimizing costs and environmental impact.

In this context, Oxy-Fuel Combustion Systems are revolutionizing the way the oil and gas industries approach energy use. By replacing traditional air-fuel combustion with oxygen-enriched processes, these systems unlock new levels of efficiency, performance, and emission control.

Understanding Oxy-Fuel Combustion Technology

Oxy-fuel combustion uses pure oxygen (or oxygen-enriched air) instead of atmospheric air to burn fuel. Unlike conventional methods, this reduces nitrogen intake, leading to higher flame temperatures and lower flue gas volumes.

The benefits are substantial:

- Higher thermal efficiency.

- Reduced fuel consumption.

- Lower CO₂, NOx, and SOx emissions.

- Improved heat transfer to the material being processed.

This is the foundation of Enhancing Efficiency with Oxy-Fuel Combustion Systems, making it one of the most promising solutions for industries dependent on energy-intensive combustion processes.

Advantages of High-Capacity Combustion Systems up to 7 MW

Industrial operations in oil and gas often require significant thermal input for furnaces, boilers, and heaters. Here, high-capacity combustion systems up to 7 MW prove indispensable.

These systems deliver:

- Consistent high performance in energy-intensive operations.

- Scalability to support both medium and large industrial setups.

- Reliability under continuous high-load conditions.

For industries where downtime means massive financial losses, high-capacity combustion systems up to 7 MW ensure stable, efficient, and dependable heat delivery.

Fuel-Efficient Oil and Gas Burners – Driving Cost Savings

The modern generation of fuel-efficient oil and gas burners has transformed industrial heating. By optimizing combustion air-fuel ratios and integrating advanced controls, these burners achieve significant reductions in fuel consumption.

Compared to conventional burners, modern systems:

- Minimize excess air losses.

- Deliver higher heat output per unit of fuel.

- Reduce operating costs while improving furnace efficiency.

In real-world applications—whether in petrochemical refineries, boilers, or reheat furnaces—fuel-efficient oil and gas burners consistently drive measurable cost savings.

Enhancing Efficiency with Oxy-Fuel Combustion Systems in Oil and Gas

In practical terms, Enhancing Efficiency with Oxy-Fuel Combustion Systems delivers multiple benefits to oil and gas operators:

- Faster heating cycles reduce overall process time.

- Significant reductions in harmful emissions.

- Improved heat transfer and better product quality.

Industries such as steel, glass, and refining have already experienced transformative results, setting benchmarks for energy and emission efficiency in heavy industrial operations.

Role of High-Capacity Combustion Systems up to 7 MW in Heavy Industry

Why does capacity matter? In high-demand industries like oil and gas, thermal requirements are massive. Systems must not only handle high capacities but also deliver efficiency under pressure.

High-capacity combustion systems up to 7 MW enable:

- Reliable performance for round-the-clock operations.

- Scalability to meet future energy demand increases.

- Reduced downtime due to robust, industrial-grade design.

By meeting both current and future heating demands, these systems provide industries with a long-term, efficient combustion solution.

Energy Savings in Oil and Gas Industries with Oxy-Fuel Systems

One of the strongest motivators for adopting oxy-fuel technology is energy savings in oil and gas industries. With reduced flue gas volumes and enhanced flame temperatures, energy use decreases substantially.

On average, industries report 10–25% savings in fuel consumption after switching to oxy-fuel systems. This translates to improved ROI, reduced operating costs, and a measurable step toward meeting corporate sustainability commitments.

Fuel-Efficient Oil and Gas Burners for Sustainable Growth

The use of fuel-efficient oil and gas burners goes beyond cost savings—it’s about building sustainable growth. These burners lower energy intensity, reduce carbon emissions, and align operations with global decarbonization targets.

As governments and customers demand greener practices, adopting fuel-efficient oil and gas burners ensures businesses remain competitive while staying compliant with emission standards.

Enhancing Efficiency with Oxy-Fuel Combustion Systems – Future-Ready Solutions

Looking ahead, Enhancing Efficiency with Oxy-Fuel Combustion Systems represents future-ready technology.

Key trends include:

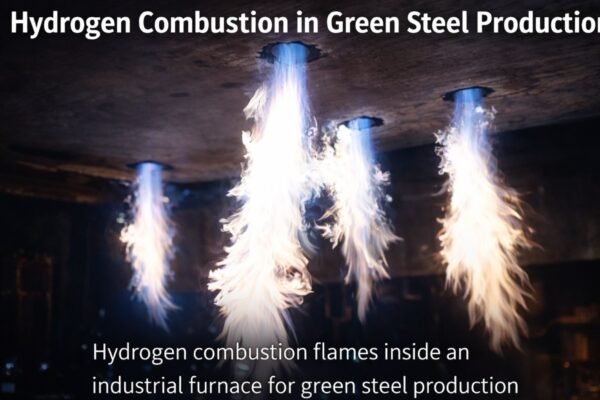

- Hydrogen-ready combustion systems.

- Integration with smart digital controls and IoT monitoring.

- Advanced automation for optimized fuel-air balance.

By embracing these innovations, industries can stay resilient in the face of evolving energy markets and sustainability requirements.

Why ENCON is a Trusted Partner for Oil and Gas Combustion Solutions

ENCON Thermal Engineers stands out as a leader in combustion solutions, offering:

- Proven expertise in customized combustion systems.

- Hydrogen-ready, energy-efficient designs tailored for the oil and gas industry.

- A track record of successful implementations across heavy industrial sectors.

From design to commissioning, ENCON ensures that clients achieve maximum efficiency, reliability, and sustainability.

Conclusion – Building a Sustainable Future with Oxy-Fuel Technology

The future of oil and gas depends on efficiency, reliability, and sustainability. By adopting oxy-fuel combustion, industries unlock higher efficiency, reduced fuel costs, and lower emissions.

With high-capacity combustion systems up to 7 MW, companies can confidently meet today’s energy demands while preparing for tomorrow’s sustainability goals.

📞 Contact ENCON Thermal Engineers today to discuss customized combustion solutions for your oil & gas requirements.