Our Exhibitions | Check Full Details Here

Revolutionizing Industrial Energy Efficiency Through ESCO Solutions

- Home

- Revolutionizing Industrial Energy Efficiency Through ESCO Solutions

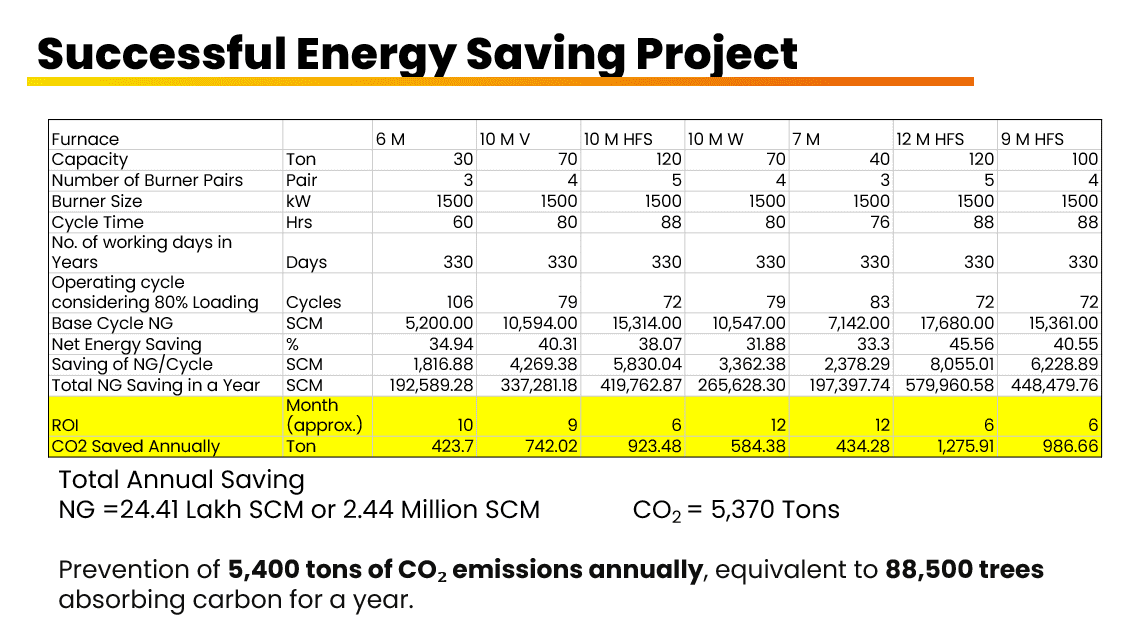

At Encon Thermal Engineers Pvt. Ltd., we are at the forefront of industrial energy efficiency with our innovative Energy Service Company (ESCO) model. Our ESCO solutions help industries reduce fuel consumption by up to 40%, significantly lower CO2 emissions, and achieve rapid ROI—typically within 9 months. By financing and implementing cutting-edge combustion technologies, we enable businesses to transition towards sustainable, low-carbon operations without upfront capital investment.

What is an ESCO?

An Energy Service Company (ESCO) provides energy-saving solutions to industries through a performance-based model, where the cost of implementation is covered by the energy savings generated. This risk-free model allows industries to adopt high-efficiency combustion systems with zero initial expenditure, ensuring sustained cost savings and environmental benefits.

Why Choose Encon’s ESCO Model?

Key Benefits:

- Zero CAPEX Investment: We finance the entire project, reducing financial barriers for industries.

- Guaranteed Energy Savings: Payment is based on actual savings, ensuring a risk-free engagement.

- Fast Payback Period: Most projects achieve ROI within 9 to 12 months.

- Advanced Energy-Efficient Technologies: Implementing regenerative burners, self-recuperative burners, oxy-fuel systems, and hydrogen combustion.

- Sustainability and Compliance: Achieve up to 60% CO2 reduction, aligning with global decarbonization goals and ESG compliance.

- Enhanced Profitability: Lower energy bills, reduced maintenance costs, and long-term operational efficiency.

- End-to-End Project Management: From energy audits to implementation and monitoring, we manage the entire process.

ESCO Technologies We Deploy

Our ESCO projects integrate the latest high-efficiency industrial combustion solutions, including:

- Regenerative Burners: Recover and reuse waste heat, improving overall efficiency by up to 40%.

- Self-Recuperative Burners: Advanced heat recovery within the burner itself, maximizing thermal efficiency.

- Oxy-Fuel Combustion: Eliminates nitrogen in combustion air, reducing fuel consumption and NOx emissions.

- Hydrogen Combustion: A future-ready solution for carbon-free industrial heating.

- Flue Gas Heat Recovery Systems: Extract waste heat from exhaust gases to further optimize energy use.

Target Industries

Encon’s ESCO model is ideal for energy-intensive industries that rely on furnaces, kilns, and heating systems, including:

- Steel Plants & Rolling Mills

- Forging Units

- Reheating Furnaces

- Aluminum Melting Plants

- Heat Treatment & Foundries

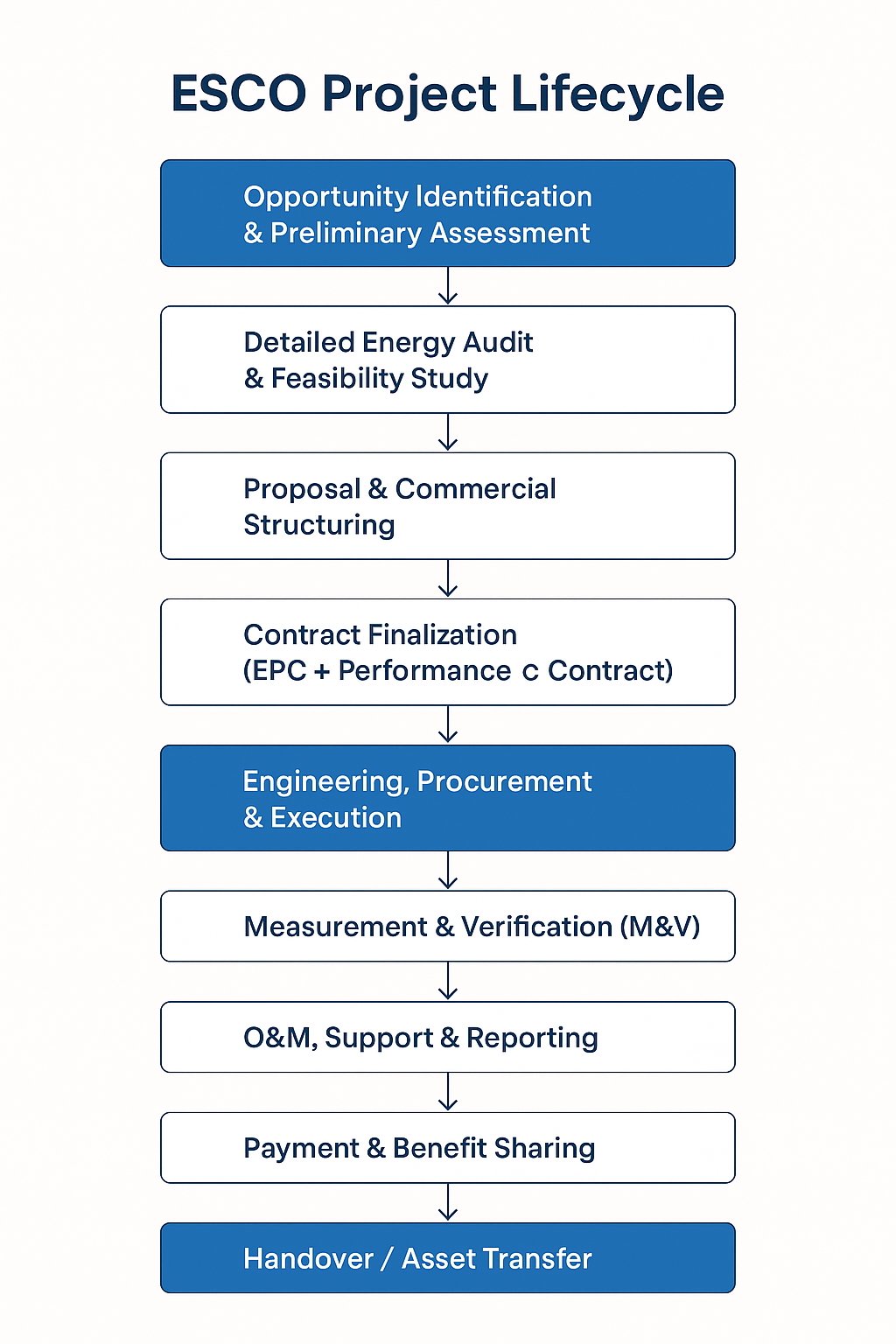

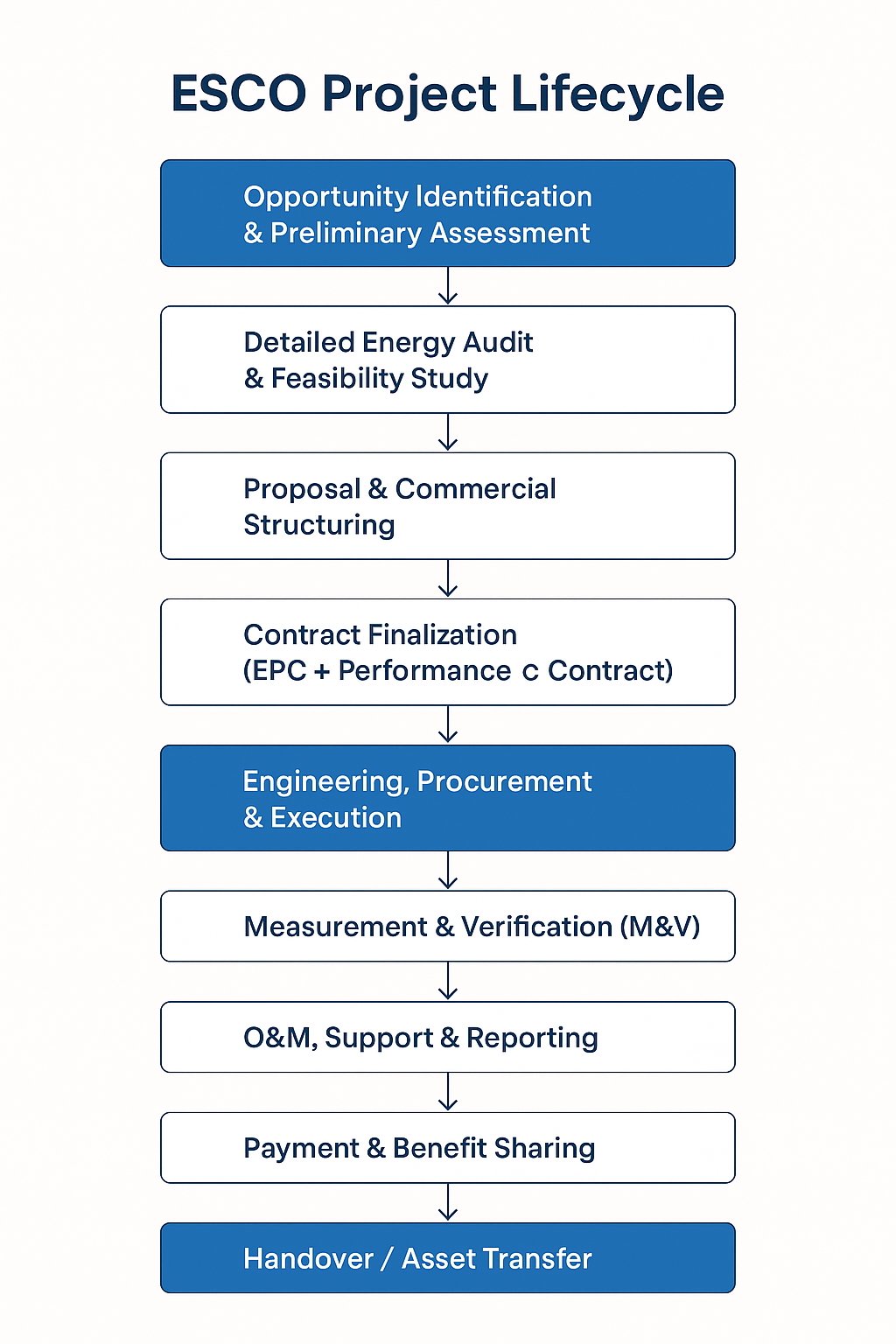

Various Stages of an ESCO Project

Mapping out each phase is crucial to ensure project success, from identifying opportunities to long-term benefit sharing. Here’s how ENCON manages the ESCO journey:

1. Opportunity Identification & Preliminary Assessment

- Client Engagement: We understand your operational goals, challenges, and energy pain points.

- Data Collection: Energy bills, production data, and past audits are reviewed.

- Preliminary Audit: A walkthrough audit to identify potential savings areas.

- Feasibility Decision: We evaluate if the ESCO model suits your needs — technically and financially.

2. Detailed Energy Audit and Feasibility Study

- Baseline Creation: Establish current fuel use and CO₂ emissions.

- Technical Audit: Deep dive into equipment, controls, and process flows.

- Savings Estimation: Projected reduction in fuel consumption and emissions.

- Technology Selection: Regenerative burners, oxy-fuel systems, automation — whatever suits best.

- CAPEX & ROI Modeling: We provide detailed investment and payback projections

3. Proposal & Commercial Structuring

- Performance-Based Proposal: Includes savings guarantees and ROI.

- Flexible Financing: Shared savings, fixed annuity, or deferred payment models.

- Carbon Credit Structuring: We evaluate and monetize CO₂ reductions.

- Contracting: Drafting MoUs or LOIs with clear risk allocation and deliverables.

4. Contract Finalization (EPC + Performance Agreement)

- Investment Terms: Ownership models and asset transfer terms defined.

- Legal Review: EPC and performance contract with enforceable savings guarantees.

- Client Sign-Off: Ready to build.

5. Engineering, Procurement & Execution

- Detailed Engineering: Thermal design, 3D modeling, instrumentation.

- Procurement & Fabrication: In-house or strategic partner manufacturing.

- Installation & Commissioning: Minimal downtime, maximum safety.

- HSE & Quality: Adherence to industrial standards and best practices.

6. Measurement & Verification (M&V)

- Post-Audit: Compare actual performance against baseline.

- Instrumentation: Real-time monitoring (SCADA, fuel meters, sensors).

- Standard Protocols: M&V as per IPMVP ensures credibility.

- Validation: Client co-verifies and signs off on achieved savings.

7. O&M, Support & Reporting

- Optional O&M: Full or hybrid O&M models available.

- Training: Client teams are trained for self-sufficiency.

- Performance Reporting: Monthly dashboards with energy, cost, and CO₂ data.

- Continuous Optimization: Remote support and onsite tuning.

8. Payment & Benefit Sharing

- Performance-Linked Payments: Based on verified savings.

- Carbon Monetization: Shared carbon credits, if applicable.

- Flexible Billing: Monthly or quarterly as per contract.

9. Handover / Asset Transfer

- End-of-Term Audit: Equipment and savings assessment.

- Transfer of Assets: As per contract (zero or token cost).

- Knowledge Transfer: SOPs, drawings, and training documentation handed over.

10. Post-Contract Engagement

- Annual Health Checks / AMC: Optional support continues.

- Scale-Up: New process lines or furnace applications.

- Carbon Credit Continuity: Continued registration and monetization of savings.

Why ESCO is the Future of Industrial Decarbonization?

With rising energy costs, stringent environmental regulations, and corporate sustainability goals, industries must adopt energy-efficient technologies to remain competitive. Encon’s ESCO model not only reduces operational expenses but also helps companies meet carbon reduction targets with ease.

Partner With Us for a Greener, More Profitable Future

Encon Thermal Engineers is committed to driving industrial energy transformation through innovative ESCO solutions. Our expertise in high-efficiency combustion and heat recovery systems ensures maximum savings and sustainability for our clients.

📩 Contact Us Today at rfq@encon.co.in to learn how Encon’s ESCO model can revolutionize your energy efficiency strategy.