Optimize Performance and Energy Efficiency in Heat Treatment Furnaces with ENCON

As a leading heat treatment furnace manufacturer, ENCON Thermal Engineers offers innovative thermal solutions to meet the complex requirements of modern industries. With decades of experience and a commitment to excellence, ENCON designs and manufactures high-performance heat treatment furnaces that ensure optimal heating processes across various industries, including automotive, aerospace, metallurgy, and more.

Our furnaces are engineered to deliver precise temperature control, uniform heat distribution, and energy efficiency, all of which are essential for achieving superior material properties such as hardness, strength, and durability. Whether you require a solution for annealing, tempering, hardening, or stress-relieving, ENCON’s advanced furnaces guarantee the performance and reliability needed to meet the demanding standards of your industry.

As both a heat treatment furnace manufacturer and supplier, ENCON offers custom solutions designed to address the specific heat treatment needs of your business, ensuring improved operational efficiency and consistent product quality.

Why Choose ENCON as Your Heat Treatment Furnace Manufacturer?

When selecting a heat treatment furnace manufacturer, it’s critical to choose a partner with proven expertise, advanced technology, and a strong reputation for delivering reliable, durable, and efficient solutions. Here’s why ENCON stands out:

-

Precision Heating for High-Quality Results: Heat treatment processes require exact temperature control to ensure that materials achieve the desired mechanical properties. furnaces are engineered to ENCON’s provide:

> Accurate Temperature Control: Our systems maintain consistent heating throughout the chamber, reducing the risk of uneven treatment and ensuring superior product quality.

> Uniform Heat Distribution: Our advanced designs ensure that all areas of the workpiece are exposed to the same temperature, enhancing the effectiveness of processes such as annealing, tempering, and quenching. -

Energy Efficiency: At ENCON, we understand the importance of reducing operational costs while maintaining high-performance standards. Our furnaces are designed to minimize energy consumption through:

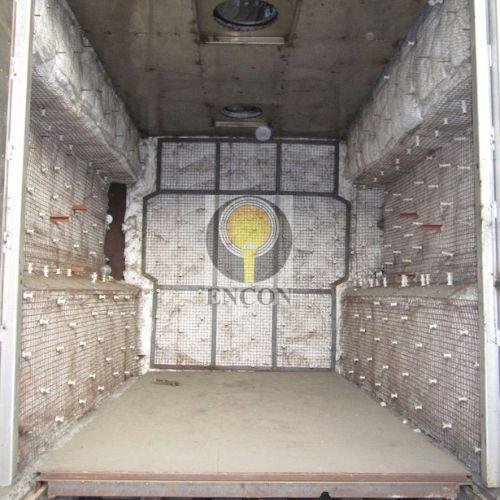

> Optimized Insulation: Our furnaces use high-quality insulation materials to reduce heat loss, ensuring that more energy is used for the heating process itself.

> Advanced Combustion Systems: By utilizing efficient burners and heat recovery systems, our furnaces consume less fuel, resulting in lower energy costs and a reduced environmental impact. - Custom-Engineered Solutions: We understand that each business has unique heat treatment needs. ENCON offers custom-engineered furnace solutions tailored to your specific process requirements. Whether you need a batch furnace for small-scale operations or a continuous furnace for high-volume production, we design systems that fit your operational goals and space constraints.

- Reliable Performance and Durability: ENCON’s heat treatment furnaces are built with robust materials and designed for continuous use in demanding industrial environments. This ensures long-term reliability and minimal maintenance, even in harsh conditions.

- Comprehensive Support: As a trusted heat treatment furnace supplier, we provide comprehensive services from initial design and installation to after-sales support. Our team of experts is available to ensure your furnace operates at peak performance, helping you achieve maximum efficiency and product quality.

At ENCON, we specialize in providing customized heat treatment furnace solutions designed to meet the diverse requirements of various industries. Our focus is on enhancing thermal efficiency, improving process accuracy, and ensuring compliance with environmental and safety standards.

Key Features of ENCON Heat Treatment Furnaces

ENCON furnaces are designed with advanced technology to ensure they meet the highest standards of performance, efficiency, and safety. Below are some of the key features that make ENCON’s heat treatment furnaces the top choice for industries worldwide:

Energy-Efficient Operation

Energy efficiency is at the core of our furnace designs. ENCON heat treatment furnaces incorporate advanced insulation, heat recovery systems, and efficient burners that help reduce fuel consumption and operational costs, making them a cost-effective choice for long-term use.

High-Temperature Capabilities

Our furnaces are capable of reaching the extreme temperatures required for various heat treatment processes. Whether you need to anneal, temper, or harden materials, our systems can deliver precise and consistent heat at temperatures up to 1,300°C, making them ideal for metals and alloys of all types.

Smart Control Systems

Our furnaces are equipped with state-of-the-art digital control systems that allow for precise temperature monitoring and control. These systems enable:

>Real-Time Data Monitoring: Operators can track temperature, pressure, and energy usage in real time, ensuring that the furnace operates within optimal parameters.

>Automated Processes: Our systems can be programmed to automatically adjust heating cycles, reducing the need for manual intervention and ensuring consistent results.

Safety Features

ENCON places a high priority on safety. Our furnaces come equipped with various safety mechanisms, including:

>Over-temperature Alarms: These ensure that the furnace remains within safe operating limits.

>Emergency Shut-Off Systems: These provide an immediate response in the event of an emergency, ensuring the safety of both operators and equipment.

>Robust Construction: Built to withstand the demanding conditions of industrial environments, our furnaces are designed for safety and longevity.

Versatile Design

ENCON offers a range of heat treatment furnace designs, including batch, continuous, and specialized furnaces for unique applications. Our versatile systems can be customized to suit the specific needs of industries ranging from automotive to aerospace, ensuring that you get the right furnace for your application.

Innovative Combustion Technology

We integrate advanced combustion technologies into our heat treatment furnaces, regenerative burners, self-recuperative burners, oxy-fuel burners, and hydrogen-ready combustion systems. These cutting-edge solutions enhance fuel efficiency, lower emissions, and ensure our furnaces are future-ready, aligning with both performance goals and environmental sustainability.

Industries Benefiting from ENCON’s Heat Treatment Furnaces

As a premier heat treatment furnace supplier, ENCON’s furnaces are used across a variety of industries that require precise heat treatment processes to improve the strength, durability, and performance of materials. Key industries include:

Automotive Industry

Heat treatment is essential in the automotive sector for enhancing the strength and durability of components such as gears, axles, and engine parts. ENCON furnaces provide the reliability and precision required to produce high-performance automotive components.

Aerospace Industry

In aerospace manufacturing, heat treatment processes are used to improve the mechanical properties of metals and alloys. ENCON’s furnaces ensure the consistent quality needed for critical aerospace components.

Construction & Heavy Machinery

Heat-treated metals are used extensively in construction and heavy machinery due to their enhanced durability. ENCON furnaces provide the precise temperature control necessary for producing materials that can withstand heavy loads and harsh conditions.

Tool and Die Manufacturing

The tool and die industry depends on heat treatment to produce hardened and tempered materials. ENCON’s heat treatment furnaces ensure that tools and dies meet the high standards required for precision manufacturing.

The ENCON Advantage: Leading Heat Treatment Furnace Manufacturer

As a leading heat treatment furnace manufacturer, ENCON is committed to delivering advanced furnace solutions that exceed industry standards. Here’s why customers around the world choose ENCON:

Proven Expertise

With decades of experience in designing and manufacturing furnaces, ENCON has established itself as a leader in thermal engineering. Our team of experts understands the complexities of heat treatment processes and works closely with clients to develop custom solutions that deliver exceptional results.

Cutting-Edge Technology

ENCON continuously invests in research and development to ensure that our furnaces incorporate the latest technological advancements. This commitment to innovation ensures that our customers receive high-performance, energy-efficient systems that deliver long-term value.

Tailored Solutions

Every industry has unique requirements when it comes to heat treatment. ENCON works closely with its customers to develop tailored furnace solutions that meet their specific operational needs, whether it’s a high-temperature batch furnace for metal hardening or a continuous furnace for high-volume production.

Comprehensive After-Sales Support

At ENCON, we don’t just sell furnaces—we provide ongoing support to ensure that your system operates efficiently throughout its lifespan. Our team is available for installation, maintenance, and technical assistance, ensuring that your furnace delivers optimal performance for years to come.

With ENCON, you’re choosing a heat treatment furnace solution that not only meets but exceeds industry expectations, delivering exceptional reliability, superior performance, and long-term energy savings.

Ready to Upgrade Your Heat Treatment Process? Contact ENCON Today!

If you’re looking for a high-performance furnace solution, ENCON Thermal Engineers is here to help. As a leading heat treatment furnace manufacturer and supplier, we offer advanced, custom-engineered systems that meet your unique production needs. Contact us today to learn how ENCON’s heat treatment furnaces can improve your operational efficiency, reduce costs, and ensure the highest product quality standards.

The ENCON Advantage: Proven Expertise and Innovation

ENCON Thermal Engineers is more than just a forging furnace supplier; we are your partners in operational success. With decades of experience in the thermal engineering industry, we have honed our expertise in designing and manufacturing furnaces that meet the evolving needs of the forging sector. Our focus on innovation ensures that our products incorporate the latest technological advancements, offering our customers the best possible performance and value.

Our commitment to technological innovation ensures that ENCON’s heat treatment furnaces are engineered for maximum efficiency and sustainability. These systems are fully compliant with the latest environmental regulations and support the adoption of eco-friendly practices in your operations.